The Challenge of Diversity: How GOBEACTOOL Enables Steel Service Centers to Master All Cuts with Fewer Blades

Steel Service Centers (SSCs) are vital links between steel mills and end-users, transforming bulk steel into customized requirements through services like cutting, shearing, slitting, and forming. In the critical service of cut-to-length processing, the efficiency of circular saw blades is paramount to profitability.

📊 The SSC Challenge: Complexity and Inventory

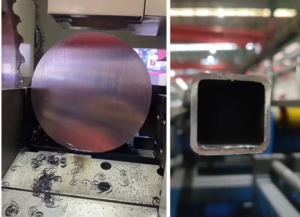

SSCs typically stock a vast array of steel products—sheets, plates, bars, tubes, and structural shapes—in all sizes and grades. To cut this diverse inventory to specification, SSCs face significant operational hurdles:

- Material Diversity: Having to cut extremely varied materials (from solid bars to thin-walled tubing), each demanding different saw blade configurations.

- High-Mix, Low-Volume Orders: Handling numerous small, diverse orders requires frequent switching of cutting tasks.

- Massive Downtime: Changing saw blades to accommodate varying material thicknesses, cutting speeds, and precision requirements results in costly production downtime and efficiency loss.

⚙️ The GOBEACTOOL Solution: Versatility Meets Durability

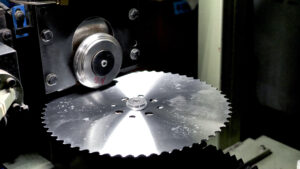

The traditional approach involves managing a complex inventory of specialized blades. GOBEACTOOL solves this by maximizing the versatility and durability of our Cermet Cold Saw Blades:

- Portfolio Analysis: Our experts analyze your entire cutting portfolio, including all material thicknesses, shapes, and grades.

- Inventory Simplification: We select and recommend a limited number of GOBEACTOOL saw blade specifications designed with versatile tooth geometries that can efficiently handle the vast majority of your jobs.

- Zero-Downtime Transition: The primary goal is to enable rapid transitions between different cutting jobs (e.g., switching from a solid round bar to a square tube) without requiring a physical blade change, thereby maximizing machine uptime.

📈 The Outcome: Boosting Operational Efficiency and Margins

By partnering with GOBEACTOOL, Steel Service Centers achieve tangible benefits:

- Significantly Reduced Downtime: Fewer blade changes lead to higher equipment utilization.

- Optimized Inventory: The need for different blade types and high stock levels is drastically reduced, lowering capital lockup.

- Guaranteed Quality: GOBEACTOOL blades provide excellent cut precision and surface finish, meeting demanding “cut-to-length” standards

📞 Contact GOBEACTOOL experts today to analyze your cutting matrix and tailor a simplified, highly efficient saw blade solution to start boosting your operational efficiency!