- I. The Dual Structure of Cermet: Sources of Hardness and Toughness

- II. The Core Conflict: The Hardness-Toughness Trade-off

- III. GOBEACTOOL’s Optimization Strategy: Customized Formulation and Grain Control

- Conclusion: Material Science Drives Superior Performance

- 📞 If your cutting task involves high-strength alloys or unique application conditions, contact our material experts for optimized formulation and design recommendations.

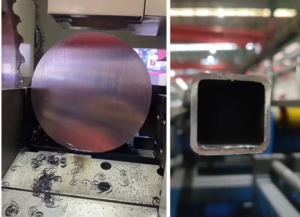

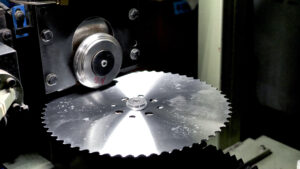

In the high-performance metal cutting sector, Cermet (Ceramic + Metal) saw blades have become the preferred alternative to traditional High-Speed Steel (HSS). However, Cermet performance is not monolithic; the central challenge lies in balancing the inherent conflict between hardness (wear resistance) and toughness (chipping resistance). GOBEACTOOL’s research and development are based on a precise understanding of this core material science principle.

I. The Dual Structure of Cermet: Sources of Hardness and Toughness

Cermet is composed of two primary elements, each contributing unique properties:

- Hard Phase (Ceramic/Carbide): Typically Titanium Carbide (TiC) and Titanium Carbonitride (TiCN). These provide the material’s extreme hardness, heat resistance, and wear resistance. They determine the blade’s anti-abrasion capability during high-speed, high-temperature operation.

- Binder Phase (Metal Matrix): Usually metals like Nickel (Ni), Cobalt (Co), or Molybdenum (Mo). During sintering, these metals bind the hard particles together, providing the material with toughness and impact resistance. They determine the blade’s ability to resist impact and vibration, preventing catastrophic chipping.

II. The Core Conflict: The Hardness-Toughness Trade-off

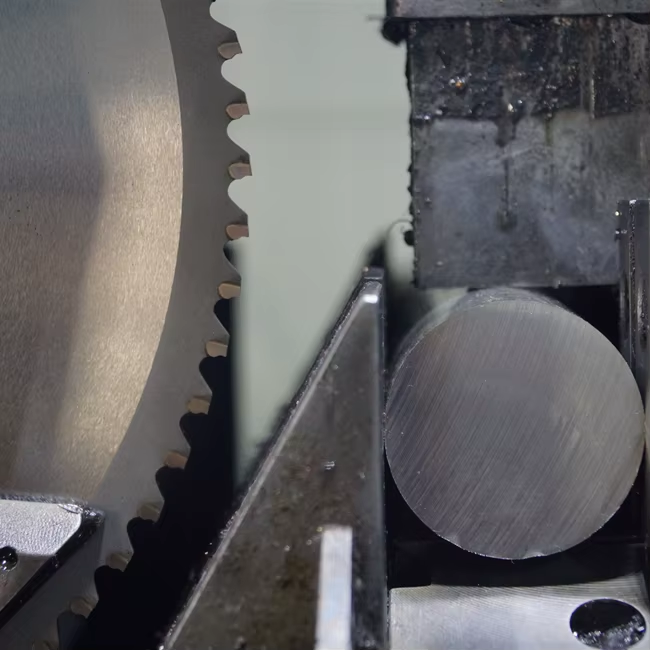

In material science, hardness and toughness typically share an inverse relationship. Every manufacturer faces this dilemma:

- If solely pursuing Hardness: Increasing the proportion of the hard phase leads to high wear resistance, but the material becomes extremely brittle. When encountering impurities, micro-cracks, or slight machine vibration, the blade is highly susceptible to severe chipping.

- If solely pursuing Toughness: Increasing the proportion of the metal binder enhances impact resistance, but hardness decreases, leading to accelerated wear, especially during high-temperature, high-speed continuous cutting.

For industrial users demanding high efficiency and low TCO, either extreme results in high costs.

III. GOBEACTOOL’s Optimization Strategy: Customized Formulation and Grain Control

GOBEACTOOL optimizes Cermet formulation across two key dimensions to meet the demands of various applications:

1. Application-Based Custom Formulation

We adjust the Cermet binder content based on the characteristics of the client’s cutting task:

| Application Scenario | Task Characteristics | GOBEACTOOL Formula Tendency | Performance Benefit |

| Flying Saw/High-Speed Pipe | Continuous cutting, high friction, high speed. | Tendency toward Medium-High Hardness, moderate binder content. | Maximizes high-temperature wear resistance for continuous service life. |

| Thick Bars/Structural Steel | Heavy load, intermittent impact, high cutting force. | Tendency toward High Toughness, increased binder content. | Enhanced impact and chipping resistance, preventing tooth fracture under load. |

2. Precise Control of Carbide Grain Size

This is key to achieving our high-performance standard. By meticulously controlling the size and distribution of the Titanium Carbide particles (hard phase):

- Ultra-Fine Grain: While maintaining high hardness, this structure effectively inhibits the spread of micro-cracks, thereby improving toughness. GOBEACTOOL uses advanced powder metallurgy to ensure uniform grain size, achieving “high toughness under high hardness.”

- Uniform Distribution: Ensuring the metal binder uniformly encapsulates the hard phase prevents hotspots and stress concentration, which is fundamental to resisting thermal shock during high-speed cutting.

Conclusion: Material Science Drives Superior Performance

The superior performance of a saw blade originates from material science investment. GOBEACTOOL is not just a manufacturer of saw blades; we are experts in Cermet material performance optimization. We understand there is no single “best” formula—only the “best customized” formula for your specific cutting task.

📞 If your cutting task involves high-strength alloys or unique application conditions, contact our material experts for optimized formulation and design recommendations.

Estimated reading time: 4 分钟