描述

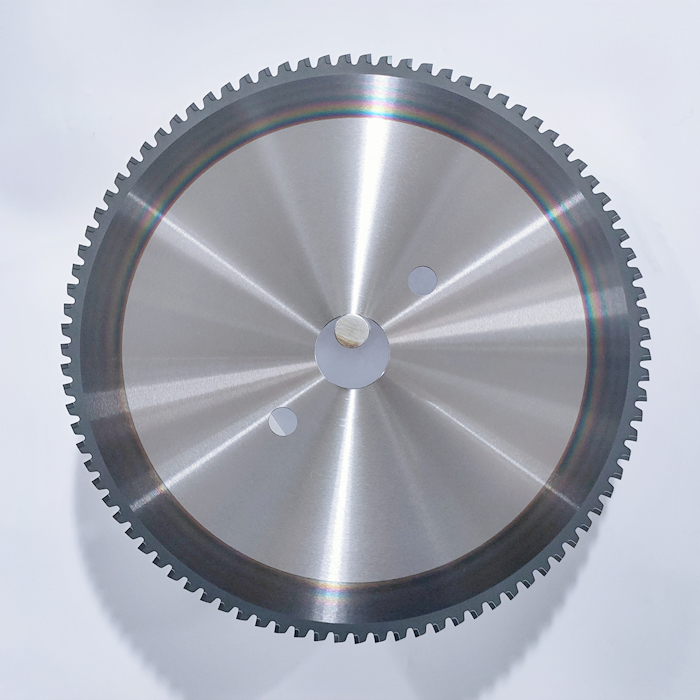

Zero-Scarf Cermet Flying Saw Blade | Eliminate Secondary Finishing in Welded Tube Mills

Overview

The GOBEACTOOL Flying Saw Blade with Inner Scarfing Capability is a specialized, dual-function solution for continuous welded pipe and tube manufacturing (ERW/HF welding). While the primary function is high-speed cut-off, this blade is designed to work seamlessly within production lines that utilize internal weld bead removal (scarfing). The blade’s geometry is robustly constructed to handle the material integrity after the internal weld bead has been removed or trimmed, ensuring the cleanest possible cut and maximizing overall line efficiency.

Key Technical Features

| Feature Category | GOBEACTOOL Advantage | Performance Benefit |

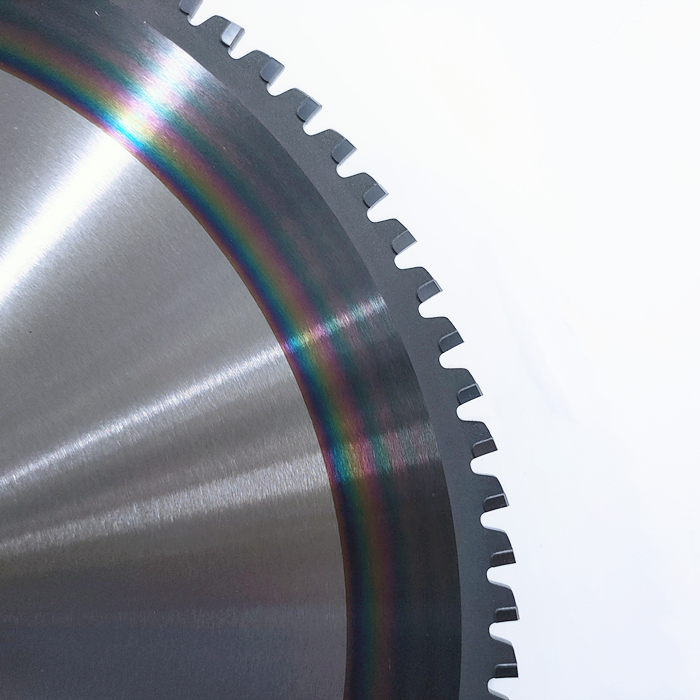

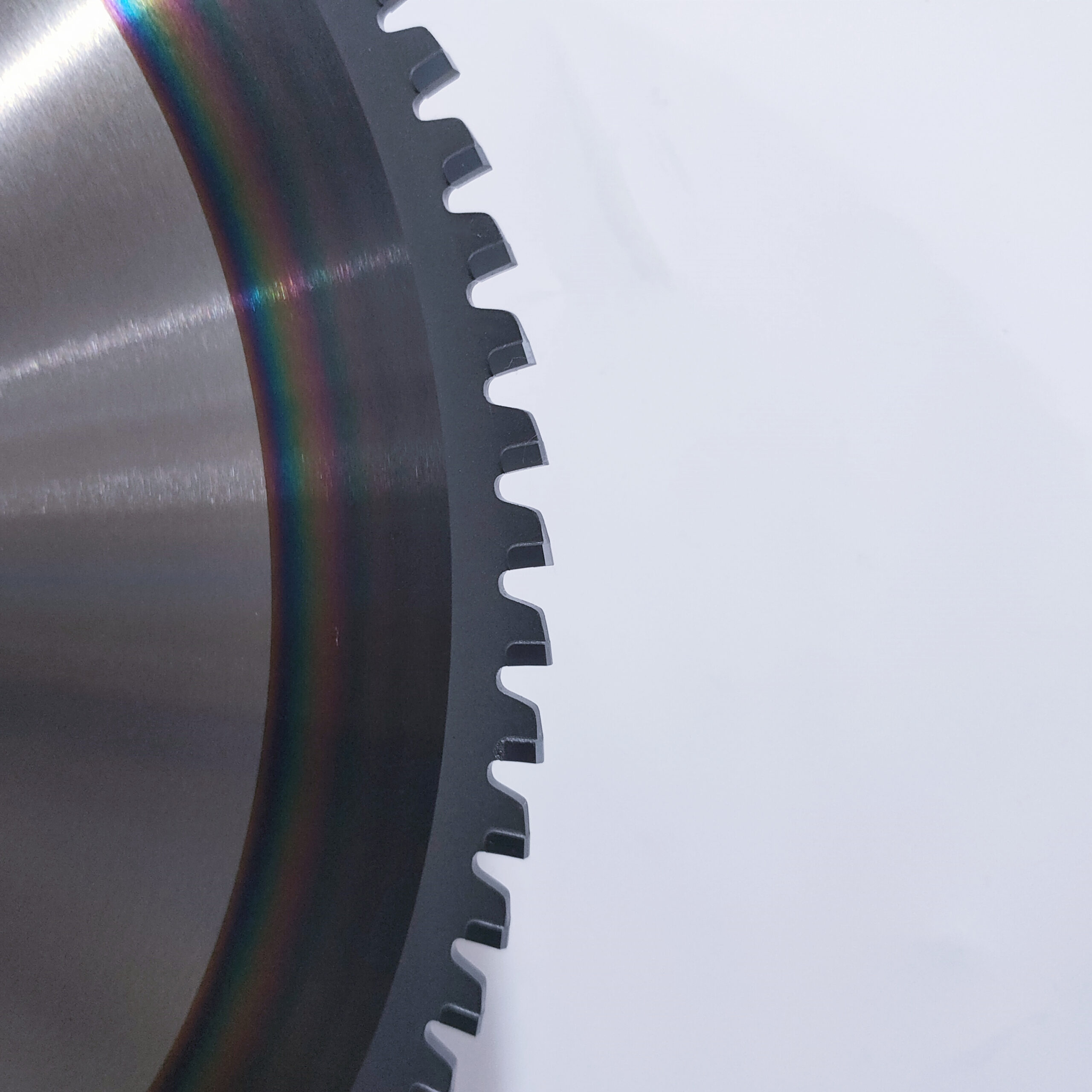

| 1. Weld-Seam Optimized Geometry | Reinforced Cutting Profile: Tooth geometry is slightly strengthened and optimized for material that has undergone pre-cutting/scarfing treatment on the internal weld bead. | Enhanced Durability: Provides reliable performance when cutting through the potentially hardened area of the material adjacent to the scarfing zone. |

| 2. High-Speed Cermet/TCT Core | Custom Material Blend: Utilizes Cermet or High-Impact TCT (depending on the material grade and wall thickness). | Consistent Line Speed: Ensures the cutting tool does not become the bottleneck, maintaining maximum throughput on continuous mills. |

| 3. Precision Clearance Angles | Minimized Friction: Specific clearance angles are maintained to ensure clean shearing of the tube wall without inducing excessive friction or lateral forces on the material. | Reduced Burr Formation: Results in a clean, square cut end that requires minimal, if any, secondary external deburring. |

| 4. Stability and Runout Control | Laser Tensioning & Balancing: Every blade is precisely tensioned and balanced for high RPM usage on flying saw systems. | Accurate Cut Length: Minimizes vibration and runout, essential for maintaining precise cut lengths at high actuation speeds. |

Ideal Application Suitability

This blade is the standard choice for high-volume tube mills that require continuous, reliable cutting and incorporate internal scarfing tools in their setup:

-

Welded Tube & Pipe Mills (with Scarfing Tooling): Designed for ERW/HF welding lines.

-

Materials: Carbon Steel, Mild Steel, and standard Stainless Steel tubing.

-

Goal: High volume output where the internal weld bead is managed by the scarfing unit prior to cutting.

Q+ Series Tube Cutting Flying Saw

Features:For cutting steel tube with inner scarfing on line

Application parameters

V=300-350m/min

SZ=0.05-0.12mm

Orbital Saw Dimensions

| Outside diameter(mm) | Kerf(mm) | Saw body thickness(mm) | Borehole(mm) | Sawtooth count |

| 250 | 3.2 | 2.5 | 45/50 | 64/72/80 |

| 300 | 3.2 | 2.5 | 80 | 52/64/72 |

| 355 | 4.0 | 3.2 | 45/80 | 64/72/84 |

| 380/400 | 4.0 | 3.2 | 115 | 52/64/72 |

Flying Saw Dimensions

| Outside diameter(mm) | Kerf(mm) | Saw body thickness(mm) | Borehole(mm) | Sawtooth count |

| 350 | 3.2 | 2.7 | 50 | 100/110/120/140 |

| 400 | 3.2 | 2.7 | 50 | 110/120/130/140 |

| 450 | 3.6 | 3.2 | 50 | 120/130/140/160 |

| 500 | 3.6 | 3.2 | 50 | 120/130/140/160 |

| 560 | 3.6 | 3.2 | 50 | 120/140/160/170 |

| 600 | 3.6 | 3.2 | 50 | 120/140/170/180 |

| 630 | 3.6 | 3.2 | 50 | 120/140/160/180/200 |

| 650 | 3.6 | 3.2 | 50 | 120/140/160/180/200 |