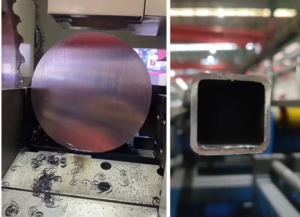

In the realm of heavy manufacturing and structural engineering, cutting thick-walled tubes (such as large-diameter, high-strength steel pipes) presents a formidable challenge. Traditional cutting methods frequently result in two primary pain points: tube mouth deformation (ovality) and severe internal/external burrs, which directly lead to expensive secondary processing costs and reduced production efficiency.

GOBEACTOOL believes that the key to solving thick-walled tube cutting issues lies not in machine power, but in the scientific customization of saw blade tooth geometry.

I. Pain Points of Traditional Cutting: Why are Deformation and Burrs Inevitable?

1. Tube Mouth Deformation (Ovality)

Although thick-walled tubes are highly rigid, they still undergo slight deformation under radial force. Traditional circular saw blades exert uneven radial loads on the tube wall during the moment of entry and exit. This often causes the tube mouth to lose its roundness (i.e., slight ovality), complicating subsequent welding or flange installation.

2. Severe Internal/External Burrs

When cutting thick-walled materials, the chip volume is high, and cutting forces are intense. Internal burrs are formed by material tearing when the blade exits the inner wall; External burrs are mainly caused by material squeezing and plastic deformation resulting from cutting forces. These burrs not only necessitate additional deburring processes but can also contaminate high-cleanliness applications like hydraulic lines.

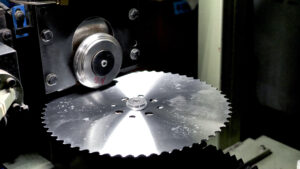

II. Core Solution: GOBEACTOOL’s Custom Tooth Geometry Optimization

By analyzing tube wall thickness, material grade, and cutting speed, GOBEACTOOL designs targeted custom tooth geometries to address these challenges.

1. The Secret to Eliminating Deformation: Balanced Cutting Force ($\mathbf{F_c}$)

- Phased Cutting: We use special composite tooth profiles (such as modified $\text{BW}$ or $\text{HZ}$ teeth) to distribute the primary cutting task among different teeth, preventing excessive single-tooth loads.

- Vibration Reduction Design: Precise pitch and minimal height variation ensure vibration is minimized during cutting, eliminating radial stress concentration and fundamentally preventing deformation.

2. The Key to Burr-Free Finish: Precise Cutting Angles and Chip Evacuation

- Optimized Rake Angle ($\gamma$): The rake angle is adjusted to promote chip curling and breaking, allowing broken chips to be quickly evacuated, reducing friction against the tube wall.

- Precision Relief Angles ($\alpha$): The side and relief angles are precisely set to ensure the blade provides a pure shearing force rather than a tearing force when entering and exiting the inner wall, minimizing internal burr formation.

- Professional Coating: Customized PVD Coatings are applied to significantly reduce the coefficient of friction, minimize chip adhesion, and ensure a cleaner cut.

Cutting thick-walled tubes is no longer a production bottleneck. Through GOBEACTOOL’s customized saw blade geometry technology, you can reinvest the time and cost originally spent on secondary processing back into higher production efficiency. We provide more than just saw blades—we deliver precision cutting engineering solutions tailored to your specific tube material and machinery.

*📞 If your production line is struggling with thick-walled tube deformation or burr issues, contact our technical team immediately for your exclusive custom saw blade solution. *