描述

Coated Tungsten Carbide Tipped (TCT) Cold Saw Blades | Heavy-Duty Performance & Optimized Heat Resistance

Overview

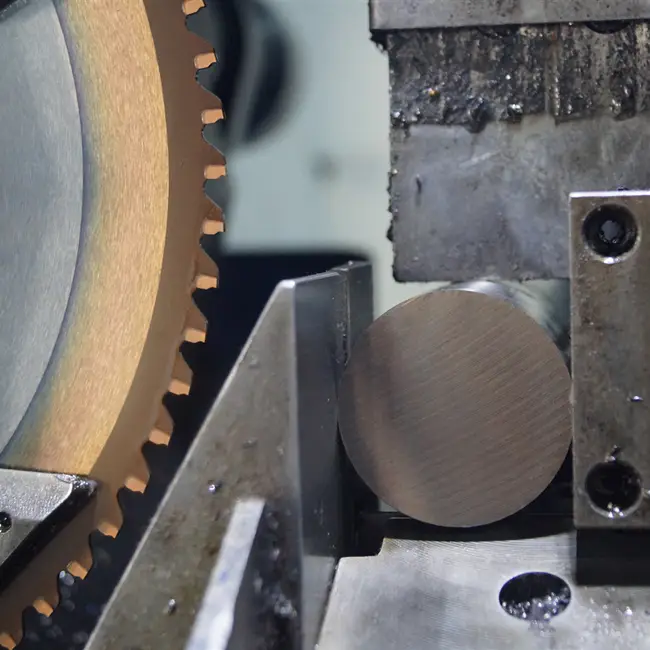

The GOBEACTOOL Coated TCT Cold Saw Blade is engineered for the most demanding heavy-duty metal cutting applications, particularly where maximum robustness and impact resistance are paramount. This blade combines the inherent high strength of Tungsten Carbide tips with an advanced PVD coating, creating a powerful tool for cutting thick-walled steel, high-strength structural profiles, and difficult-to-machine stainless steel grades. The synergistic effect of TCT toughness and friction-reducing coating ensures reliable, high-speed output and superior longevity.

Key Technical Features

| Feature Category | GOBEACTOOL Advantage | Performance Benefit |

| 1. TCT Carbide Grade | High-Impact Carbide Formula: Utilizing a specific, tough Tungsten Carbide grade selected for its exceptional transverse rupture strength (TRS). | Maximum Robustness: Ideal for handling heavy profiles, uneven surfaces, and intermittent cuts without premature tip breakage. |

| 2. PVD Coating Shield | Thermal and Friction Barrier: Application of a high-performance PVD coating (e.g., TiAlN, AlTiN). | Optimized Heat Dissipation: The coating acts as a heat shield, protecting the carbide tips from thermal shock and oxidation at the cut zone, significantly extending edge life. |

| 3. Enhanced Base Plate | Vibration Dampening & Stability: Blade core features proprietary dampening slots and precise tensioning. | Accurate Heavy Cutting: Maintains stability and accuracy during deep cuts and large material contact areas, reducing noise and improving finish quality. |

| 4. Geometry for Strength | Reinforced Tooth Profile: Optimized geometry designed to withstand the higher loads associated with thicker material processing. | Efficient Chip Removal: Ensures clean and efficient swarf evacuation, preventing chip welding and tool overload in robust cutting tasks. |

Ideal Application Suitability

This blade is the go-to solution for applications demanding both high toughness and extended wear life on difficult materials:

-

Thick-Walled Steel & Pipe: Cutting thick structural components and large diameter pipes.

-

Heavy Profiles & Beams: Ideal for fabrication shops cutting heavy structural members.

-

High-Strength Stainless Steel: Efficient processing of Austenitic and Duplex stainless steels.

-

General Heavy-Duty Cold Sawing: Where cutting parameters exceed the optimal range for standard HSS or Cermet.

Coated Tungsten Carbide Tipped Cold Saw Blade

Features:Cutting medium to high carbon steel, long life.

Application parameters:

V=50-70m/min

SZ=0.035-0.05mm

Cutting life:

305 about 20 m2