描述

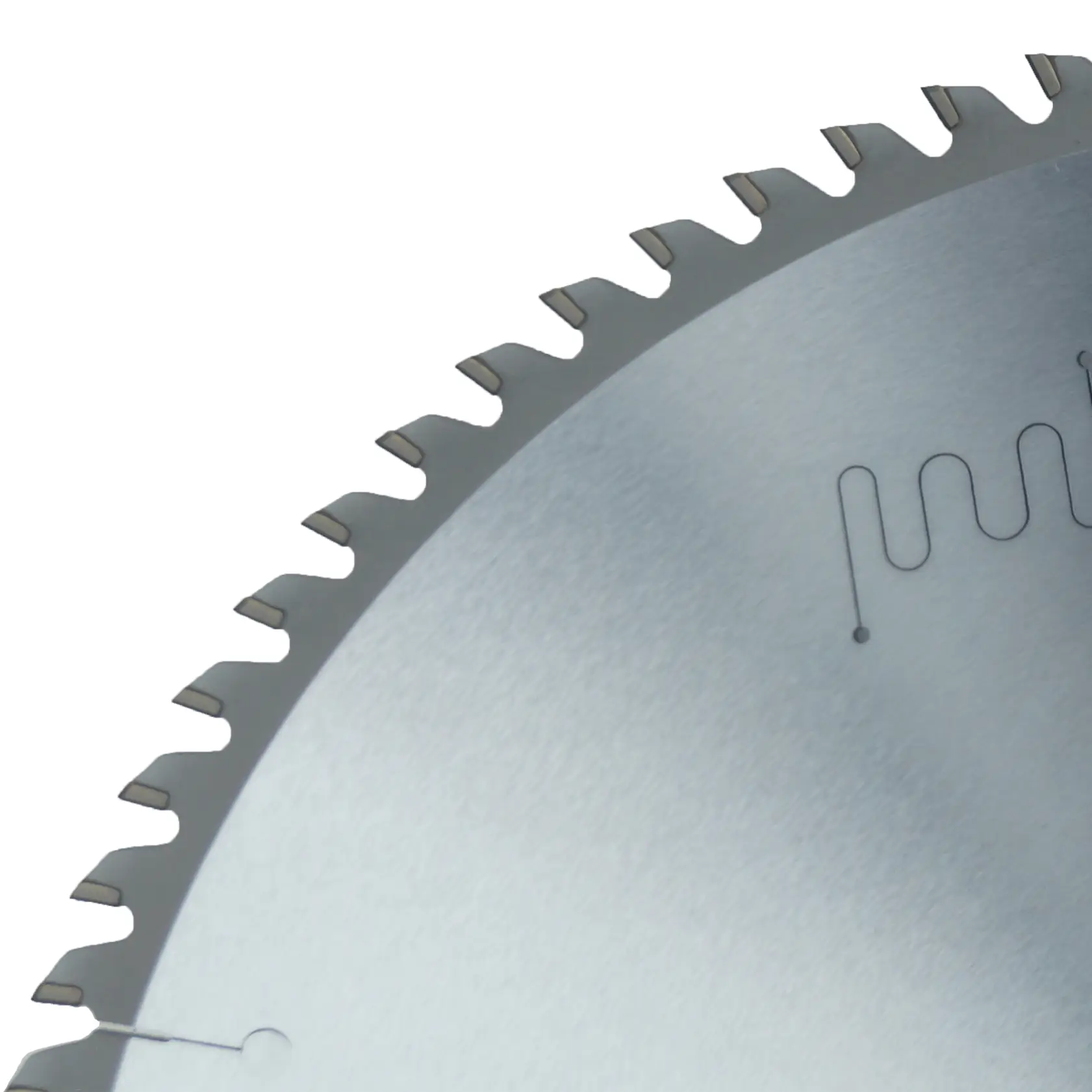

PCD Tipped Saw Blades for Aluminum | Ultra-Long Life & Precision for High-Silicon & Abrasive Alloys

Overview

The GOBEACTOOL PCD Tipped Saw Blade for Aluminum is the ultimate solution for challenging non-ferrous applications where conventional Tungsten Carbide (TCT) blades rapidly fail due to extreme abrasion. This blade is specifically engineered for cutting high-silicon aluminum alloys (above 12% silicon), abrasive aluminum castings, and other highly demanding non-ferrous materials. Featuring precision-brazed Polycrystalline Diamond (PCD) tips, this blade offers unparalleled tool life, exceptional cutting accuracy, and superior surface finish, drastically reducing tooling costs and machine downtime in high-volume production.

Key Technical Features

| Feature Category | GOBEACTOOL Advantage | Performance Benefit |

| 1. Polycrystalline Diamond (PCD) Tips | Extreme Hardness & Wear Resistance: PCD is significantly harder and more abrasion-resistant than Tungsten Carbide, especially against abrasive particles like silicon. | Ultra-Long Tool Life: Achieves hundreds of times longer lifespan than TCT blades in high-silicon aluminum, leading to massive TCO savings and reduced tool changes. |

| 2. High-Precision Brazing | Advanced Laser & Vacuum Brazing: Ensures an extremely strong and stable bond between the PCD tip and the saw body, critical for handling high cutting forces. | Superior Tip Retention: Minimizes the risk of tip loss, even under demanding industrial cutting conditions. |

| 3. Optimized Blade Geometry | Application-Specific Design: Precision-ground tooth profiles (often TCG or modified TCG) are engineered to manage the unique chip characteristics of abrasive aluminum. | Excellent Surface Quality: Delivers clean, smooth, burr-free cuts with minimal material deformation, crucial for precision components. |

| 4. Vibration & Heat Management | Laser-Cut Expansion Slots & Dampening: Features specialized design elements in the steel body to absorb vibration and dissipate heat efficiently. | Enhanced Stability & Accuracy: Maintains optimal cutting performance and tight tolerances, essential for high-volume, automated production lines. |

Ideal Application Suitability

This PCD Tipped blade is indispensable for specific, high-demand non-ferrous cutting scenarios:

-

High-Silicon Aluminum Alloys: Engine blocks, automotive pistons, complex castings.

-

Abrasive Aluminum Castings: Components with high wear properties.

-

Precision Extrusions: Where tool life and dimensional accuracy are paramount.

-

Large Volume Production: Industries requiring minimal downtime and maximum tool longevity.

PCD Tipped saw blade for Aluminum

Features:

Cutting artificial wood board

Low cutting noise

long service life

PCD saw blades last 20-30 times longer than TCT saws