描述

Tungsten Carbide Coating Band Saw Blades | Extreme Resistance for Abrasive & Hard Alloys

Overview

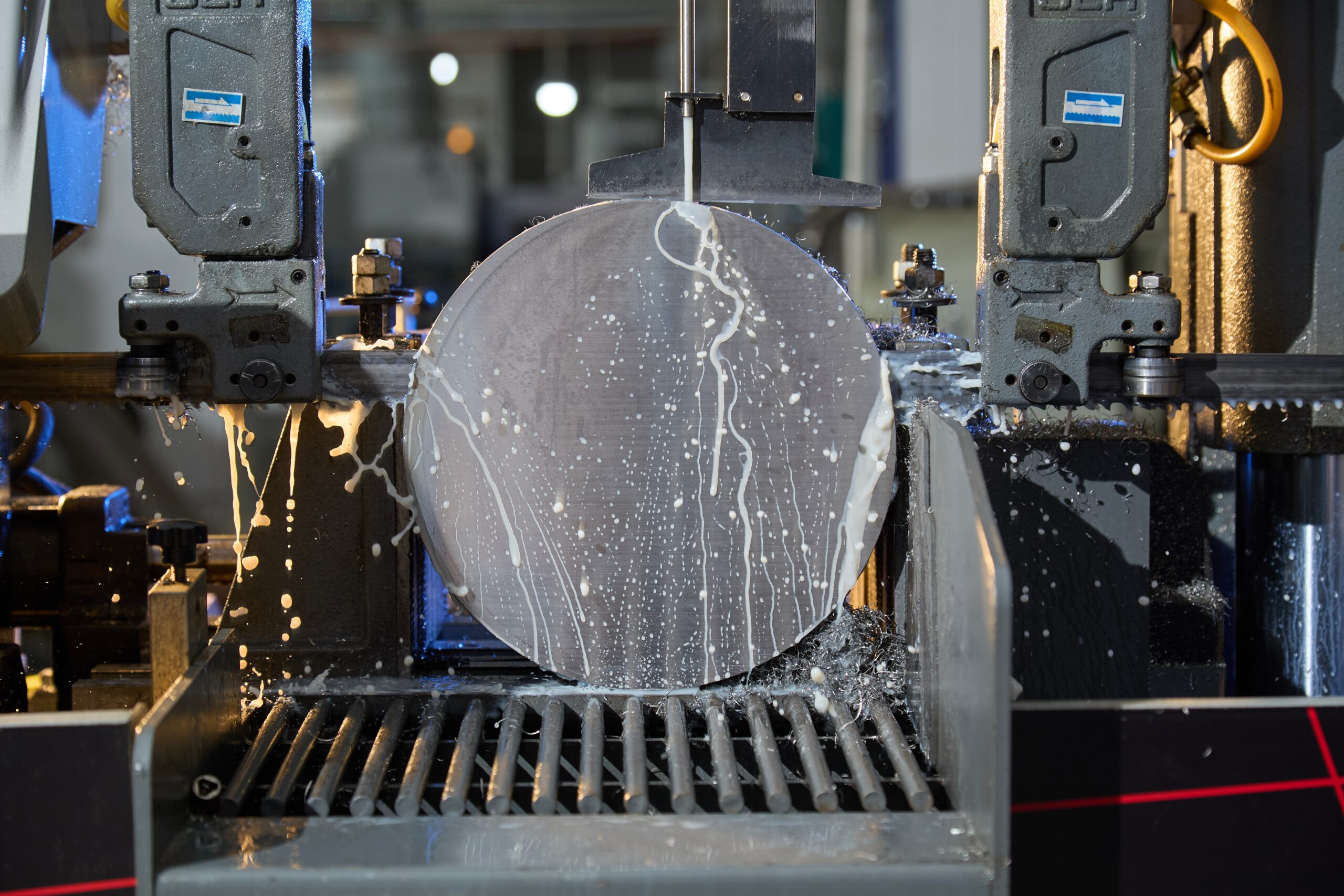

The GOBEACTOOL Tungsten Carbide Coating Band Saw Blade is engineered to conquer the toughest cutting challenges that rapidly destroy conventional bi-metal blades. This blade is designed for processing highly abrasive materials, hardened steels, and difficult exotic alloys (such as Titanium and Inconel). The blade features a precision-applied Tungsten Carbide cutting edge, providing superior hardness and heat resistance necessary for achieving reliable output in heavy-duty sawing applications.

Key Technical Features

| Feature Category | GOBEACTOOL Advantage | Performance Benefit |

| 1. Tungsten Carbide Edge | High-Hardness Cutting Surface: The cutting edge utilizes a robust application of Tungsten Carbide, the industry standard for abrasive resistance. | Extreme Durability: Maintains cutting performance on materials with high hardness (e.g., case-hardened steel) or significant abrasive content (e.g., cast iron). |

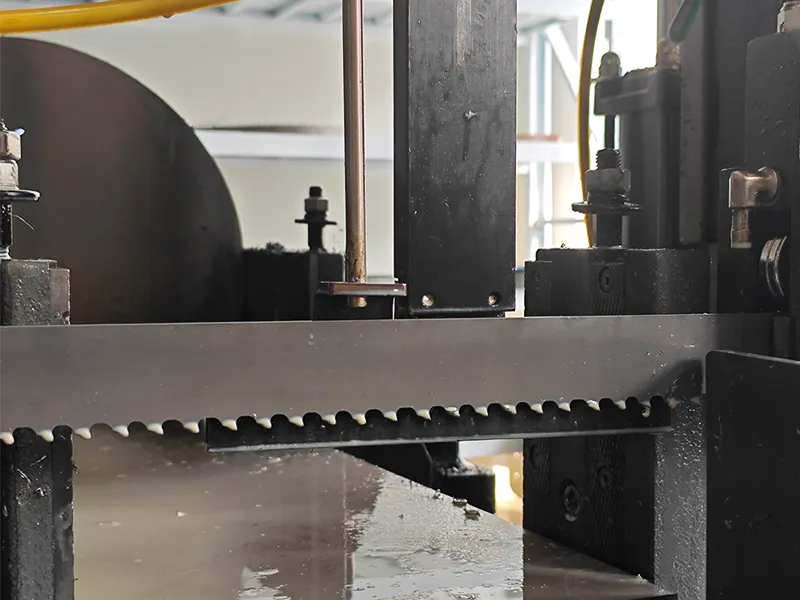

| 2. Fatigue-Resistant Backing | Premium Steel Substrate: The backing material is specially selected for high fatigue strength and flexibility. | Extended Band Life: Withstands the constant flexing required by the band saw wheel system, minimizing premature breakage. |

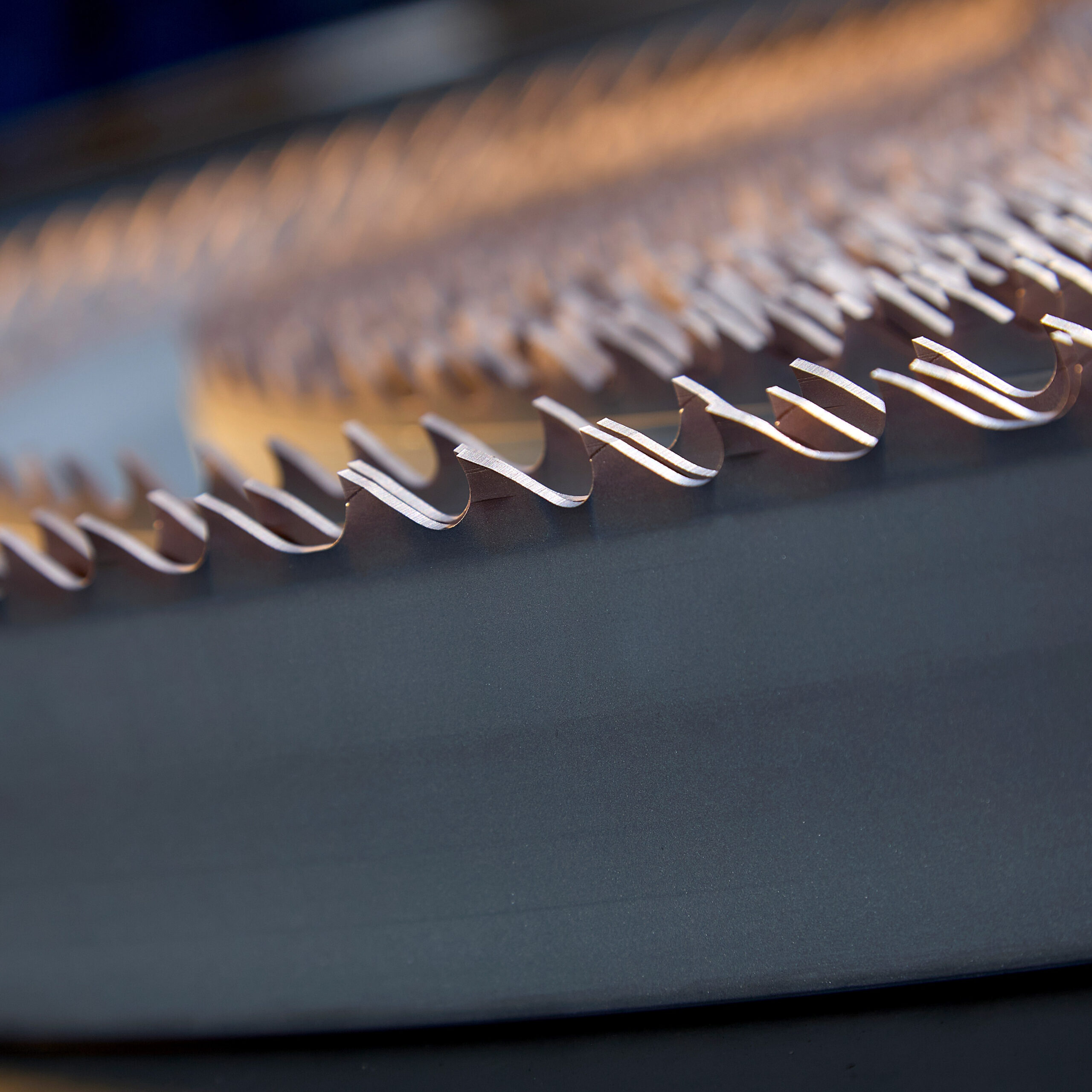

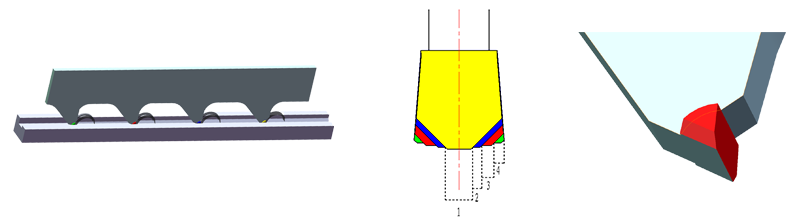

| 3. Optimized Tooth Geometry | Specialized Profile: Tooth forms are designed with a large chip capacity and reinforced geometry to handle the slow, heavy feed rates required by exotic alloys. | Efficient Swarf Removal: Ensures high-volume chips from difficult materials are removed effectively, preventing tooth damage and extending cutting time. |

| 4. Surface Treatment | Advanced Set/Grind: Available in specialized tooth sets (e.g., gritted or zero-set) optimized for minimizing frictional heat during deep cuts. | Stable Cutting Performance: Reduces drag and vibration, leading to straighter cuts and better surface finish on demanding materials. |

Ideal Application Suitability

This band saw blade is the solution for materials that cannot be efficiently cut by standard HSS blades:

-

High-Hardness Materials: Heat-treated, hardened steels (HRC 45} and above).

-

Abrasive Materials: High-silicon aluminum, graphite, chilled cast iron.

-

Exotic Alloys: Nickel-based alloys (Inconel), Titanium alloys, and specialty tool steels.

★ Cutting efficiency increased 30% ★ Cutting life increased 35%

● Unique chip-breaking tooth design (our patented product), with multiple chip separation, smoother chip discharge, greatly reducing sawing resistance.

● High-precision grinding process ensures better cutting accuracy.Micro-edge anti-chipping treatment makes highspeed sawing more stable and reliable.

● Nano-scale ultra-hard coating,provides long sawing life.

Product Application

Titanium alloy and pure titanium, high-temperature alloys, duplex stainless steel and other difficult to saw special materials.