Ensuring Maximum Performance from Your Cermet Cold Saw Blades

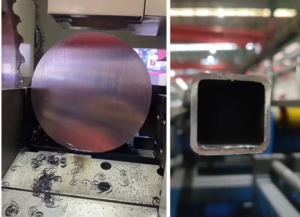

Cermet Cold Saw Blades are the ultimate tool for boosting metal cutting efficiency and surface finish quality. However, due to their material properties (high hardness but relative brittleness), proper usage and parameter settings are critical. Follow this GOBEACTOOL expert guide to achieve the longest possible blade life and best performance.

I. Pre-Installation Checks and Preparation

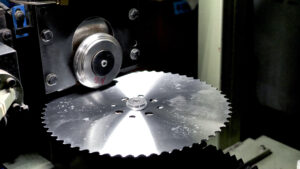

Correct installation forms the foundation for stable cutting:

Precise Mounting: Ensure the blade is mounted in the correct rotation direction. Tighten the clamping nut evenly and firmly to ensure the blade sits flat.

Inspect Machine Condition: Ensure the saw machine (especially spindle bearings and clamping system) is in good condition, free from excessive vibration or play.

Clean the Flanges: Thoroughly clean the clamping flanges. Any dust or residue can cause blade runout at high speeds, which is a primary cause of tooth chipping.

II. Core Cutting Parameter Settings (The Critical Factor)

Cermet blades rely on precise parameters. Remember: A stable feed rate is more important than blindly increasing cutting speed.

🛠️ Expert Tip: Start with the manufacturer’s recommended medium settings and adjust gradually. If vibration occurs, prioritize reducing the cutting speed while checking feed stability.

| Parameter | Goal | Optimization Principle |

| Cutting Speed (v_c) | The peripheral speed of the blade edge (m/min). | Typically ranges from 80 – 250\text{ m/min}. Use lower speeds for high-strength steel, medium-high for low-carbon steel. |

| Feed per Tooth (f_z) | The thickness of material cut by a single tooth (mm/tooth). | Maintaining proper f_z is crucial. Too low f_z causes rubbing/wear; too high f_z causes chipping. |

| Feed Rate (v_f) | The speed at which the blade advances into the workpiece (mm/min). | Prioritize stable v_f. The feed must be smooth, without sudden stops or starts, ensuring uniform pressure on each tooth. |

III. Cooling and Lubrication Management

Cermet saws are “cold saws,” but this does not mean cooling is unnecessary:

- Coolant Selection: Use a high-quality, high-lubricity water-soluble emulsion or oil-based cutting fluid.

- Coolant Application: Ensure the coolant flow is sufficient and accurately directed onto the tooth’s cutting zone to effectively carry heat away and prevent the teeth from softening.

IV. Common Troubleshooting (DOs & DON’Ts)

| Wrong Practice (DON’Ts) | Correct Practice (DOs) |

| ❌ Suddenly interrupting the feed or rapid retraction. | ✅ Maintain steady feed and smooth retraction. |

| ❌ Continuing to cut when the machine vibrates or jumps. | ✅ Stop immediately and check the spindle and clamping system. |

| ❌ Setting the feed per tooth too low (rubbing friction). | ✅ Increase the feed slightly to ensure stable, curled chips are formed. |

| ❌ Ignoring chip color and shape. | ✅ Observe the chips: Ideal chips should be silver or light blue (indicating good heat dissipation). |

📞 Summary and Technical Support

Correct usage is the key to maximizing the life of your GOBEACTOOL blades. If you have questions about specific materials or settings for new equipment, do not hesitate.

Contact our technical support team today for expert guidance and maximize your cutting efficiency!