Five Steps to Choosing the Perfect Cutting Tool for Your Application

Selecting the right saw blade should not be based on guesswork, but on rigorous analysis of your application needs. Follow this five-step guide to ensure you select the GOBEACTOOL blade that maximizes your equipment’s performance.

Step 1: Define Application and Material (Foundation)

This crucial first step determines the blade material and basic design:

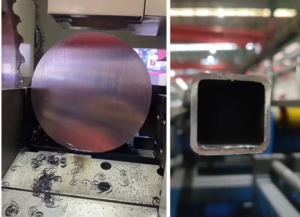

- Metal Cutting: Cutting carbon steel, stainless steel, tubes, or solid bars? (Choose Cermet Cold Saws or HSS blades).

- Wood Cutting: Cutting solid wood, plywood, or MDF? (Choose Woodworking Carbide-Tipped Blades).

- Material Type: Are you cutting solid material or thin-walled tubing? This directly influences the tooth count and geometry.

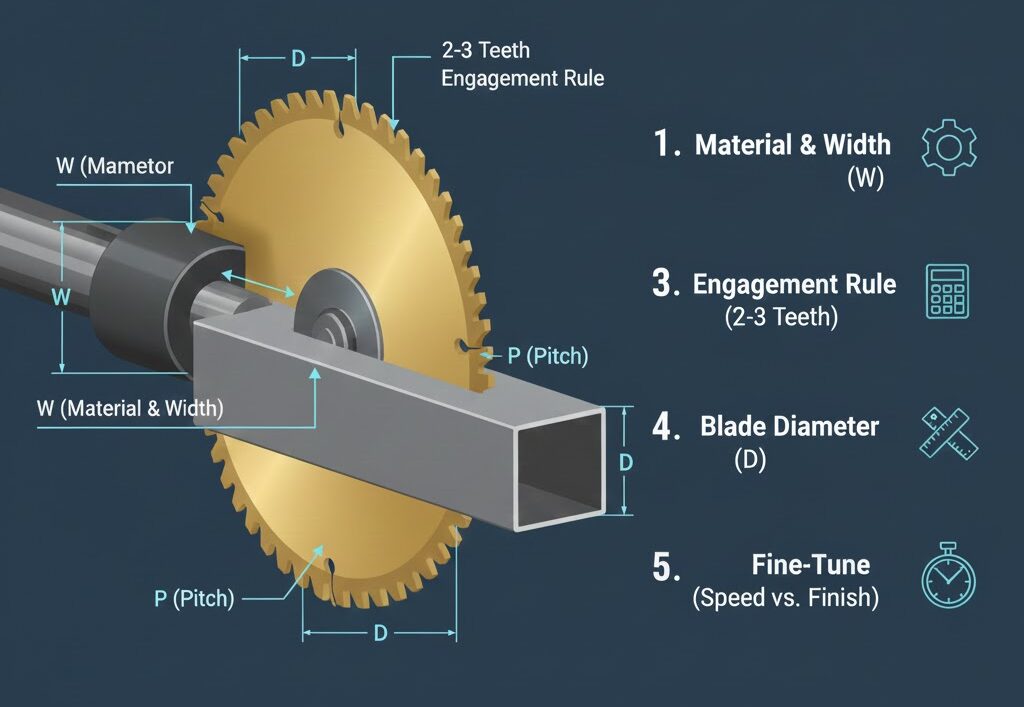

Step 2: Determine Blade Specifications (Machine Match)

You must precisely measure and match your cutting equipment:

- Diameter (D): Must comply with the machine’s safety guard and maximum cutting depth requirements.

- Arbor Hole (d): Must perfectly match the spindle diameter to ensure stable and precise running.

- Kerf (Thickness): Thinner kerfs save material but stability must be considered.

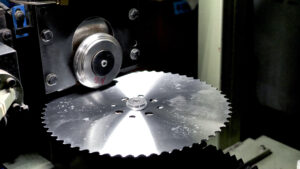

Step 3: Define Tooth Count and Geometry (Balancing Quality vs. Speed)

The tooth count (Z) is a key factor influencing cutting quality and speed:

- Low Tooth Count (Z less): Ideal for fast cutting or thick materials (e.g., thick-walled tubes, solid bars). Provides large chip space but a rougher finish.

- High Tooth Count (Z more): Required for cutting thin materials or applications demanding a very high surface finish (e.g., thin stainless steel pipe). Slower cutting but provides a smoother finish.

- Tooth Geometry: Must be matched to the material. For metal tubes, enhanced composite teeth (like BW/HZ) may be necessary.

Step 4: Choose Blade Material (The GOBEACTOOL Advantage)

Selecting the right blade material is paramount in metal cutting:

| Material Type | Ideal Application | GOBEACTOOL Advantage |

| Cermet | High-Performance Metal Cutting (carbon steel, stainless steel, profiles). The superior replacement for traditional HSS. | Core Product. Durability increased many times over HSS, faster cutting speeds, and superior finish quality. |

| HSS | General-purpose metal cutting or applications where lower precision is acceptable. | We offer high-quality HSS for transitional or cost-sensitive projects. |

| Carbide | Suitable for wood, aluminum, or non-ferrous metals. | Our woodworking blades use premium carbide for maximum sharpness and long life. |

Step 5: Match Machine Parameters (Unlocking Performance)

Even with the correct blade, it must be matched with correct machine parameters to deliver performance:

- Machine Rigidity: High-performance blades (like Cermet Cold Saws) must run on highly rigid, low-vibration CNC equipment.

- Cutting Speed (v_c) and Feed Rate (v_f): Strictly follow GOBEACTOOL’s recommended parameters to ensure the teeth operate under optimal force and heat dissipation conditions.

📞 Summary and Expert Advice

Choosing the right saw blade is the first step in reducing your Total Cost of Ownership (TCO).

If you are unsure which specification or material is best for your specific application, contact the GOBEACTOOL expert team immediately. We will provide precise technical advice based on your material and equipment to ensure you achieve maximum cutting efficiency.