GOBEACTOOL Maintenance Experts: Simple Daily Care to Double Your Blade Lifespan

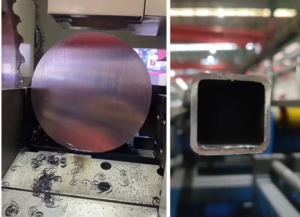

For high-performance GOBEACTOOL saw blades, especially the high-value Cermet Cold Saws, daily maintenance is not just routine—it’s a critical investment in achieving the lowest Total Cost of Ownership (TCO). Correct maintenance significantly reduces chipping, improves cutting precision, and maximizes the blade’s service life.

I. Daily Checks and Operational Norms

Operators should conduct the following checks before and after every use:

- Check Cleanliness: Immediately after each cutting task, remove chips and residue from the tooth gullets and the blade body. Adhering chips hinder heat dissipation and cause abnormal friction and overheating during the next cut.

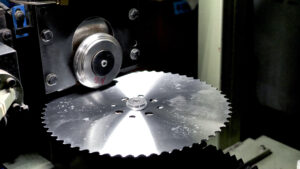

- Inspect Tooth Condition: Carefully check the teeth for chipping, cracks, or noticeable wear. If even a small chip is found, send the blade for sharpening immediately to prevent the damage from escalating.

- Stability Check: Ensure the blade is flat and tightly secured on the spindle. Any radial or face runout due to improper mounting is the leading cause of chipping and reduced blade life.

II. Lubrication and Cooling System Management

Maintaining a healthy cooling system is essential for cold sawing success:

- Coolant Quality: Regularly check the concentration and cleanliness of your coolant (cutting oil/emulsion). Contaminated or diluted coolant loses its lubrication and cooling properties, leading to overheating of the saw tips.

- Precise Application: Ensure the coolant line is clear and the nozzle is precisely aimed at the cutting zone of the teeth, not just spraying on the blade surface.

III. Scheduled Professional Maintenance

In addition to daily checks, professional, periodic maintenance is vital:

- Timely Re-sharpening: Never wait until the teeth are severely dull or cut quality degrades significantly. Sharpening should be done immediately when cutting resistance starts to increase or chip color darkens.

- Professional Sharpening: Cermet saw blades must be sharpened by professional service providers using high-precision equipment. Incorrect grinding angles can permanently damage the blade’s performance.

- Periodic Fixture Check: Check the wear condition of the spindle and clamping flanges at least monthly to ensure the fixture provides even and adequate support to the blade.

IV. Proper Handling and Storage

Preventing physical damage is the final defense for extending lifespan:

- Handle with Care: The saw teeth, especially the Cermet tips, are very hard but brittle. Strictly avoid collision or dropping during loading, unloading, and transport.

- Dry Storage: Blades should be stored on dry, flat shelves, preferably lying flat. Avoid moisture to prevent rusting or warping of the blade body.

📞 Summary and Technical Support

Blade maintenance is a preventive measure that ensures the stable operation of your production line. By standardizing these daily care procedures, your GOBEACTOOL saw blades are guaranteed to deliver a longer service life and sustained premium performance.

If you need recommendations for professional sharpening services or encounter any technical issues during use, please contact our technical support team!