内容

In the field of metal processing, the precision, surface quality, and production efficiency of cuts are key indicators of success. If your work primarily involves cutting metal, understanding the unique advantages of the Cold Saw Blade is the secret to enhancing your work quality and efficiency.

The Cold Saw Blade, as the name suggests, is designed to complete cuts in a “cold” state. But which types of jobs is this tool suited for? And why does it stand out among other saw blades?

1. The Type of Job Determines Your Cutting Needs

Before purchasing any cutting tool, you must first clarify your type of work. The cold saw blade is not a universal tool, but it offers advantages that traditional friction saws or abrasive cutting wheels simply cannot match:

A. Jobs with Extremely High Requirements for Cut Quality

If you need a smooth, flat surface that requires minimal to no secondary finishing, the cold saw blade is the ideal choice:

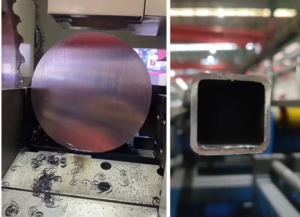

- Application Scenarios: Cutting tubes, pipes, and profiles that require high-precision fit-up and need no deburring or trimming before welding.

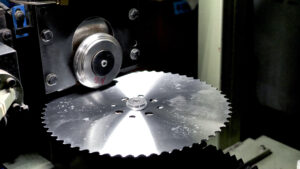

- Cold Saw Principle: The cold saw blade performs precise machining at lower rotational speeds and high torque. During the cut, most of the heat is carried away by the chips, keeping the workpiece at a low temperature. This effectively prevents material thermal deformation, hardening, and burrs.

- Result: Achieves a smooth and burr-free surface finish, with minimal perpendicularity tolerance (e.g., Perpendicularity within 3 mils).

B. Jobs Involving Cutting High-Strength Metals

Cold saw blade materials (such as Cermet or Tungsten Carbide Tipped – TCT) boast high hardness and wear resistance, specifically designed for cutting difficult-to-machine metals:

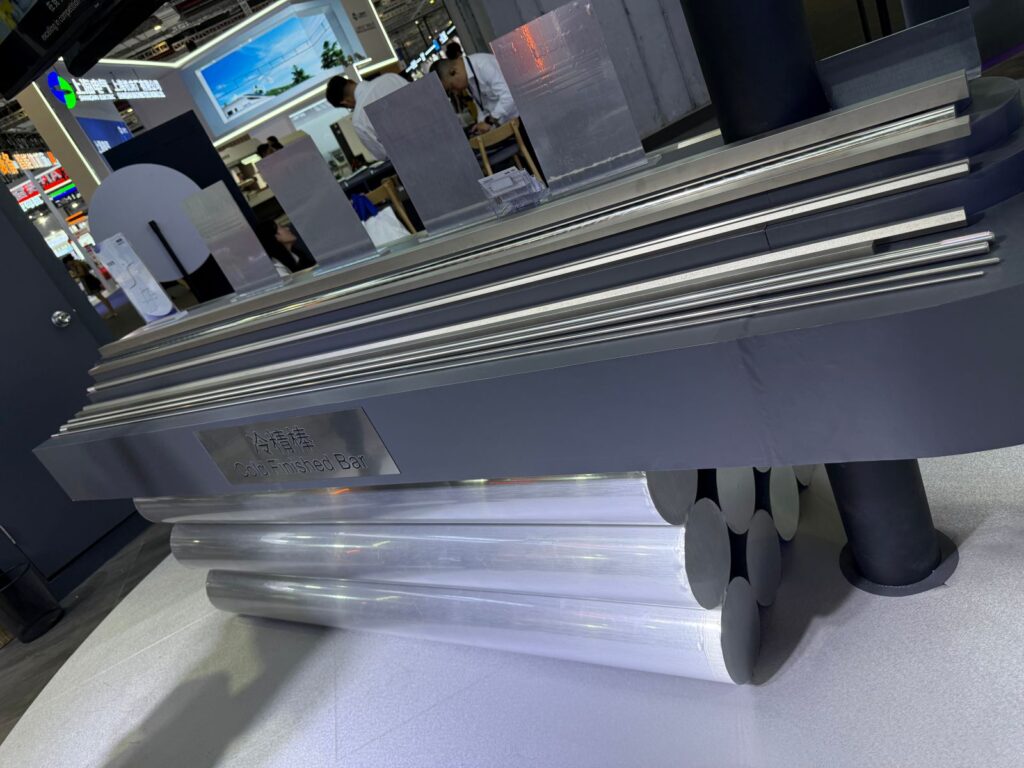

- Cermet Cold Saw Blade: Primarily used for cutting medium and high carbon steel, alloy steel, and other high-strength materials.

- TCT Cold Saw Blade: Primarily used for cutting various stainless steel materials.

If you frequently cut these high-strength, high-toughness metals, the cold saw blade offers a longer service life and faster cutting speed.

C. Jobs on High-Production Efficiency and Continuous Production Lines

In industrial environments pursuing high production efficiency, the stability and speed of the cold saw blade are crucial:

- High-Efficiency Cutting: Cold saw blades allow for a higher chip load per tooth (e.g., The chip load per tooth is 4 mils), significantly reducing the time for a single cut.

- Continuous Operation: They can withstand continuous, high-intensity work, making them perfectly suited for integration into automated production processes.

- Flying Saw Applications: On high-speed, continuous production lines, such as Tube/Pipe Cutting Flying Saws, the cold saw blade is a standard configuration, executing precise cuts while the material moves at speed.

2.Summary of Cold Saw Blade Core Advantages

| Advantage | Problems with Traditional Cutting Methods (e.g., Friction Saws) | Cold Saw Blade Solution |

| Low-Temperature Cutting | High heat leads to material deformation, oxidation, and burned edges. | Keeps the workpiece cool, preventing material property changes. |

| High Surface Quality | Rough cut surfaces, excessive burrs, requiring secondary grinding. | Smooth and burr-free surface finish, saving subsequent processing costs. |

| High Productivity | Short tool life, frequent replacement, slow cutting speed. | High production efficiency, long tool life, suitable for continuous production. |

| High Precision | Difficult to control precision, large perpendicularity tolerance. | Perpendicularity within 3 mils, meeting strict accuracy requirements. |

3. Choose Your “Cold” War Tool

Whether you are cutting various types of tubes and pipes, stainless steel materials, or medium and high carbon steel, the cold saw blade is the ideal choice for ensuring high-quality cutting results while boosting production efficiency.

When selecting a blade, determine your choice based on the material you are cutting (e.g., Coated TCT Cold Saw Blade for stainless steel, Cermet Cold Saw Blade for carbon steel), ensuring your tool is perfectly matched to your job type.

Say goodbye to burrs and inefficiency, upgrade your cutting toolkit, and welcome the new era of high efficiency and precision brought by the cold saw blade!