The Ultimate Tool for Unlocking Pipe Cutting Efficiency and Profit Margins

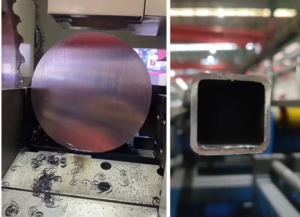

In high-speed pipe and tube rolling production lines, the cutting phase is the critical bottleneck determining overall throughput. Traditional methods or standard blades often fail under the high-frequency, high-velocity impact of the flying saw machine. GOBEACTOOL’s Coated Cermet Cold Saw Blades are precisely engineered to overcome this challenge.

I. The Flying Saw Challenge: Speed’s Strain on the Blade

A Flying Saw must synchronize with the moving pipe, meaning:

- Extreme Frequency of Impact: The blade must engage and exit the material in milliseconds.

- Intense Momentary Heat: High friction and speed generate massive instantaneous heat, which is the primary cause of wear and chipping in conventional blades.

- Demand for Stability: Any minor blade failure results in costly production line stoppages.

II. Coating Technology: The “Invisible Armor” for Performance

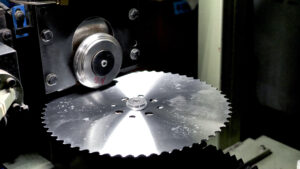

GOBEACTOOL Flying Saw Cold Saw Blades utilize a high-performance Cermet substrate combined with advanced PVD (Physical Vapor Deposition) coating technology. This coating is the key to performance breakthrough:

- Superior Heat Resistance: The coating significantly raises the working temperature tolerance of the tooth, effectively transferring cutting heat to the chips and preventing the tooth from softening or annealing during high-speed operation.

- Reduced Friction: The smooth coating surface minimizes friction during cutting, enabling smoother chip flow and further reducing energy consumption and heat buildup.

- Anti-Adhesion: The coating resists the adhesion of metal chips to the tips, keeping the teeth sharper for longer.

III. Three Key Benefits: Maximizing Production Output

By upgrading to GOBEACTOOL Coated Flying Saw Cold Saw Blades, you immediately gain the following benefits, which directly impact your bottom line:

- Extended Tool Life, Reduced Downtime: Coated blades can achieve a lifespan 50% or more longer than uncoated equivalents. Fewer blade changes maximize production line uptime.

- Achieve High-Speed, Burr-Free Cutting: The coating guarantees stability at maximum cutting speeds, resulting in a smooth finish and eliminating or significantly reducing the need for secondary deburring.

- Optimized TCO (Total Cost of Ownership): While the initial investment in coated blades is slightly higher, the combination of longer life, higher efficiency, and less rework results in a substantial reduction in the overall cost per meter of cut pipe.

Conclusion: Choose GOBEACTOOL for Stable High Output

In the high-speed tube cutting sector, the saw blade is no longer a simple consumable—it’s a precision engineering tool that dictates efficiency. Choosing GOBEACTOOL Coated Flying Saw Cold Saw Blades means choosing a solution designed and validated for high-speed, high-output production.

📞 Contact our Flying Saw technology experts today to customize a coated blade solution optimized for your pipe specifications and line speed!