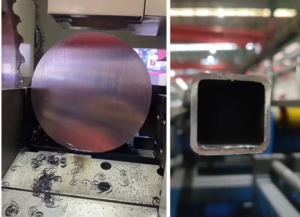

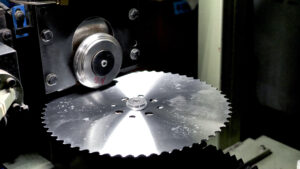

In the fiercely competitive global manufacturing sector, efficiency and quality are paramount. If you are still relying on traditional cutting methods, you may be facing challenges such as slow cutting speeds, poor surface finish, high secondary processing costs, and rapid tool wear.It’s time to upgrade your cutting tools! Cermet Cold Saw Blades are the key to overcoming these issues. As a revolutionary tooling technology, they are redefining the standards of metal cutting.

1 Cold Saw Blades Basic Concepts

| English | Explanation |

| Cermet (Ceramic + Metal) | A composite material combining the high hardness of ceramic and the toughness of metal. |

| Cold Sawing | A low-speed, low-temperature cutting process that removes most heat through the chips, achieving spark-free, high-precision cuts. |

| Advantages | Extremely high wear resistance, longer tool life, and superior cutting surface finish. |

2 Operation and Maintenance Essentials

| Key Poin) | English Description) |

| Equipment | Must use a dedicated cold saw machine with high rigidity and low vibration. |

| Cutting Parameters | Surface speed and feed per tooth must be precisely set to balance efficiency and blade life. |

| Cooling & Lubrication | Adequate supply of dedicated cutting oil or emulsion is mandatory. |

| Maintenance | When the blade dulls, it must be sent for timely and professional resharpening. |

3 Cold Saw Blades Applications and Coatings

| Aspect | English |

| Main Applications | Cutting ferrous metals such as carbon steel, alloy steel, and stainless steel. |

| Common Coatings | TiCN (Titanium Carbonitride), used to increase hardness and reduce friction. |

| Coating Purpose | Extend blade life and improve heat resistance and anti-sticking properties. |

Cold Saw Blades