Five-Step Buying Guide: How to Select the Correct Saw Blade Tooth Count (Z) for Your Cutting Task

The saw blade tooth count (Z) is a critical parameter that dictates cutting quality, speed, and tool lifespan. Too many teeth can lead to excessive friction and accelerated wear, while too few can cause chipping and a rough surface finish. Follow this five-step guide to select the optimal tooth count for your GOBEACTOOL saw blade.

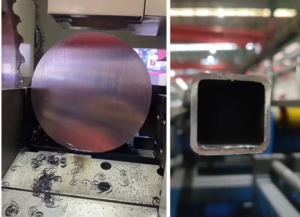

Step 1: Determine the Material Thickness and Shape (W)

Before choosing the tooth count, you must determine the material’s maximum contact thickness (W).

- Cutting Solid Bars: W equals the bar diameter.

- Cutting Square Tubes/Profiles: W equals the wall thickness.

- Cutting Tubes/Profiles: W is the single wall thickness, which determines the load on an individual tooth.

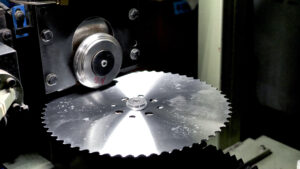

Step 2: Master the Core Principle: The 2-3 Teeth Engagement Rule

In high-performance metal cutting, the fundamental principle is to ensure that at least 2 to 3 teeth are simultaneously engaged with the material’s cutting surface (W).

- If fewer than 2 teeth are engaged: The single tooth load is too heavy, which often leads to chipping or severe vibration.

- If more than 3 teeth are engaged: The gullet space becomes insufficient, chips cannot be evacuated smoothly (clogging), leading to excessive friction and blade overheating.

Step 3: Calculate the Ideal Tooth Pitch (P)

The Tooth Pitch (P) is the distance between two adjacent teeth. This is the basis for calculating the correct tooth count.

The ideal tooth pitch (P) should be slightly greater than W/3 and less than W/2.

Essentially, the material’s contact thickness (W) should fall within the range of 2 to 3 tooth pitches.

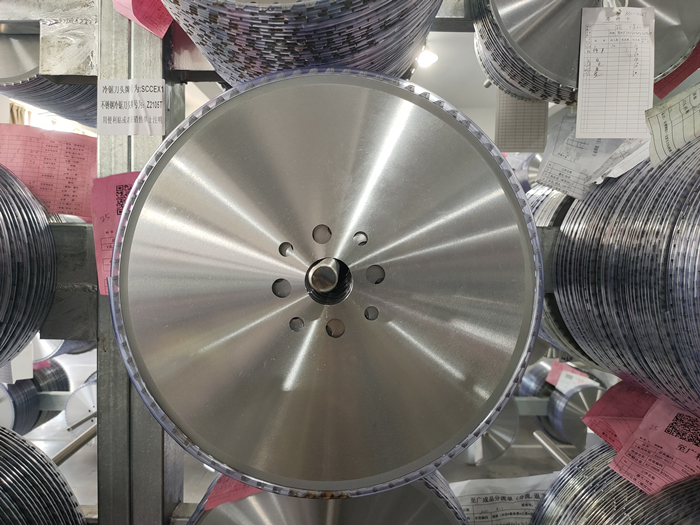

Step 4: Determine the Total Tooth Count (Z) Based on Blade Diameter (D)

With the ideal tooth pitch (P), you can now calculate the required total tooth count (Z) based on the outer diameter (D) of your saw blade:Z=π×D/P

Step 5: Final Adjustment Based on Cutting Requirements

After calculating the ideal range, make final adjustments based on your emphasis on cut quality versus cutting speed:

| Target Focus | Adjustment Direction | Resulting Impact |

| High Surface Quality | Choose a slightly higher tooth count (e.g., Z=100) | Finer chips, smoother surface, but slightly slower cutting speed. |

| High Cutting Speed | Choose a slightly lower tooth count (e.g., Z=72) | Larger chip capacity, smoother chip evacuation, faster cutting speed, but slightly rougher surface. |

| Thin-Walled Tubing | Must choose a high tooth count, strictly following the 3-4 teeth engaged rule. | Ensures the teeth do not pierce the thin wall, preventing deformation or chipping. |

📞 Summary and Expert Support

Selecting the right saw blade tooth count is a combination of science and practical experience. Choosing the correct Z value is essential for ensuring your GOBEACTOOL blade achieves maximum performance and lifespan.

If you are cutting multiple materials or high-strength alloys and require precise advice on tooth count and geometry, please contact our technical experts today.