描述

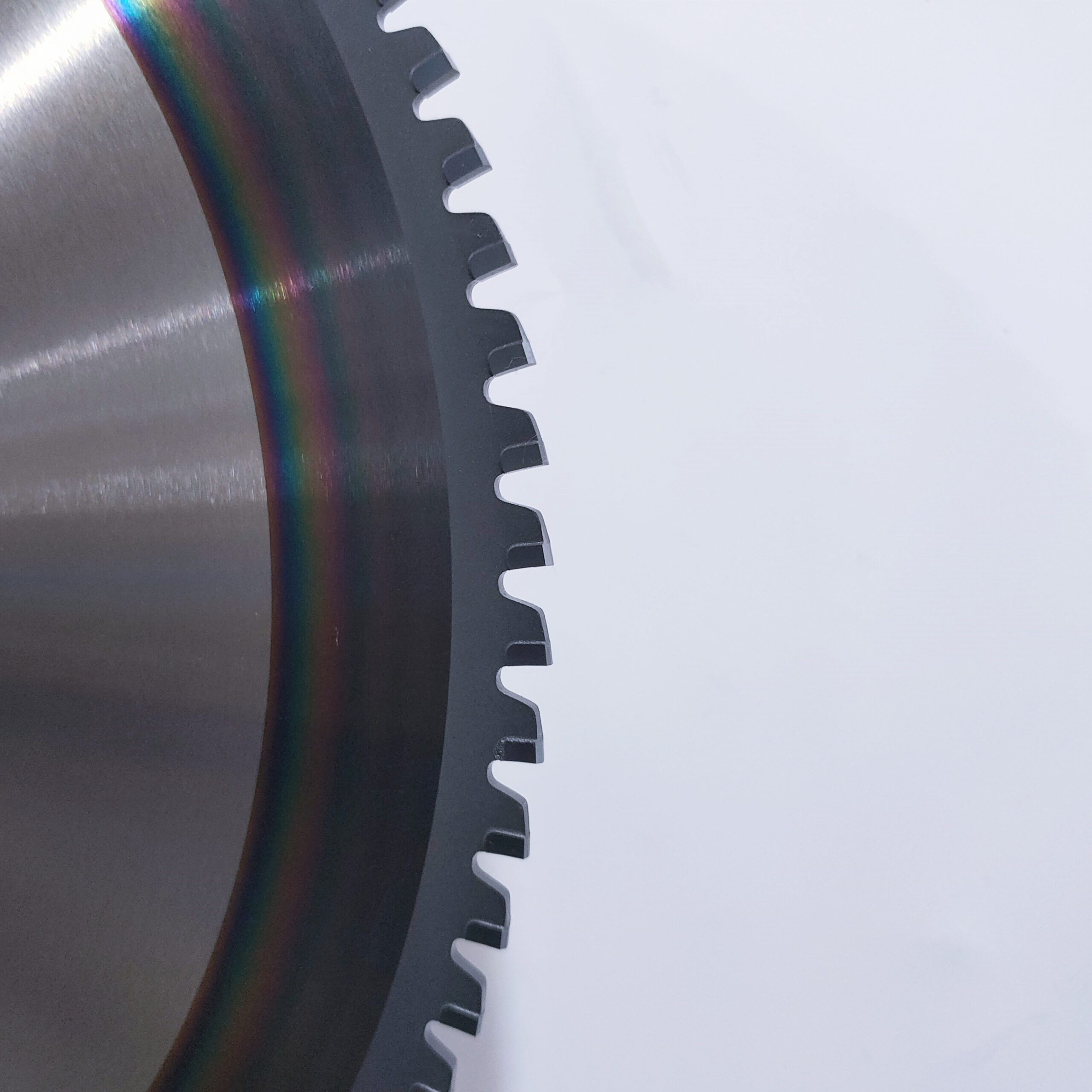

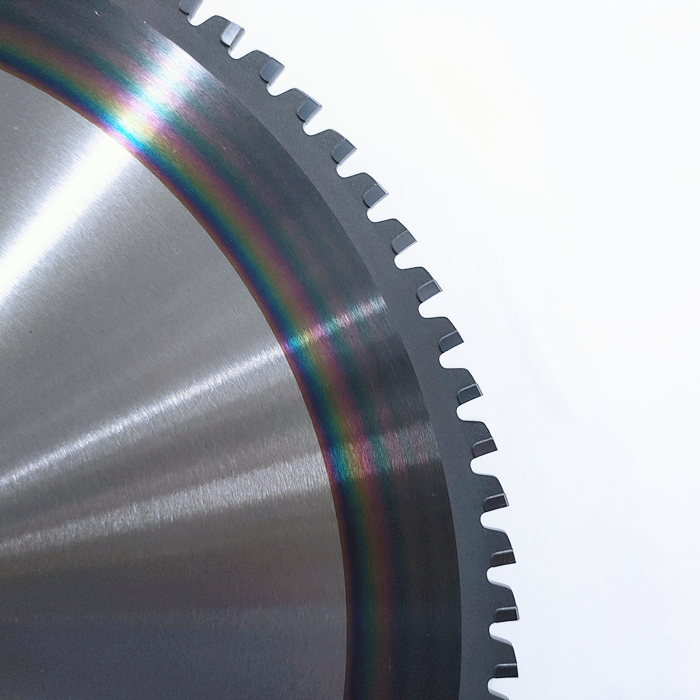

Zero-Scarf Cermet Flying Saw Blade | Eliminate Secondary Finishing in Welded Tube Mills

Overview

The GOBEACTOOL Zero-Scarf Cermet Flying Saw Blade is a specialized, high-performance solution engineered to address the critical production bottleneck of welded tube manufacturing. This blade is designed with proprietary tooth geometry and coating technology that achieves such a smooth, high-precision cut that it virtually eliminates the need for internal weld bead removal (scarfing) or heavy external deburring in subsequent operations. This translates directly into maximized line speed, reduced material waste, and the lowest Total Cost of Ownership (TCO) per cut in high-speed applications.

Key Technical Features

| Feature Category | GOBEACTOOL Advantage | Performance Benefit |

| 1. Zero-Scarf Geometry | Patented Multi-Segment Tooth Profile: Features a unique clearance angle and controlled rake to shear the material cleanly, managing the weld seam without inducing excessive burr or material deformation. | Seamless Output: Delivers a ready-to-use pipe end finish, often allowing manufacturers to bypass the dedicated deburring or scarfing station entirely. |

| 2. High-Speed Cermet Core | Enhanced Durability Formula: Custom Cermet blend optimized for the extreme rotational speeds and intermittent engagement of flying saw systems. | Maximum Uptime: Superior wear resistance maintains cutting consistency over thousands of cuts, drastically reducing tool change downtime. |

| 3. Precision PVD Coating | Anti-Friction Surface: Specialized coating reduces heat generated at the weld seam (the hardest point of the cut). | Increased Lifespan: Protects the Cermet tips from thermal fatigue and micro-chipping caused by cutting hardened weld beads. |

| 4. Structural Stability | Vibration Dampening Design: Base plate stress-relieved to handle the shock and vibration inherent to high-speed flying saw actuation. | Consistent Quality at Speed: Ensures dimensional accuracy and minimal runout, even at maximum line speeds. |

Ideal Application Suitability

This blade is indispensable for manufacturers focused on high-quality, high-speed tube production:

-

Welded Tube Mills (ERW, HF): Essential for maximizing throughput and quality on continuous production lines.

-

Materials: Carbon Steel, Mild Steel, and Stainless Steel tubing where interior weld bead is a concern.

-

Goal: Eliminating bottlenecks caused by secondary finishing or cutting quality issues.

Zero-Scarf Cermet Flying Saw Blade

Specificities:For cutting steel tube without scarf on line

Application parameters

V=300-350m/min

SZ=0.05-0.12mm

Orbital Saw Dimensions

| Outside diameter(mm) | Kerf(mm) | Saw body thickness(mm) | Borehole(mm) | Sawtooth count |

| 250 | 3.2 | 2.5 | 45/50 | 64/72/80 |

| 300 | 3.2 | 2.5 | 80 | 52/64/72 |

| 355 | 4.0 | 3.2 | 45/80 | 64/72/84 |

| 380/400 | 4.0 | 3.2 | 115 | 52/64/72 |

Flying Saw Dimensions

| Outside diameter(mm) | Kerf(mm) | Saw body thickness(mm) | Borehole(mm) | Sawtooth count |

| 350 | 3.2 | 2.7 | 50 | 100/110/120/140 |

| 400 | 3.2 | 2.7 | 50 | 110/120/130/140 |

| 450 | 3.6 | 3.2 | 50 | 120/130/140/160 |

| 500 | 3.6 | 3.2 | 50 | 120/130/140/160 |

| 560 | 3.6 | 3.2 | 50 | 120/140/160/170 |

| 600 | 3.6 | 3.2 | 50 | 120/140/170/180 |

| 630 | 3.6 | 3.2 | 50 | 120/140/160/180/200 |

| 650 | 3.6 | 3.2 | 50 | 120/140/160/180/200 |