描述

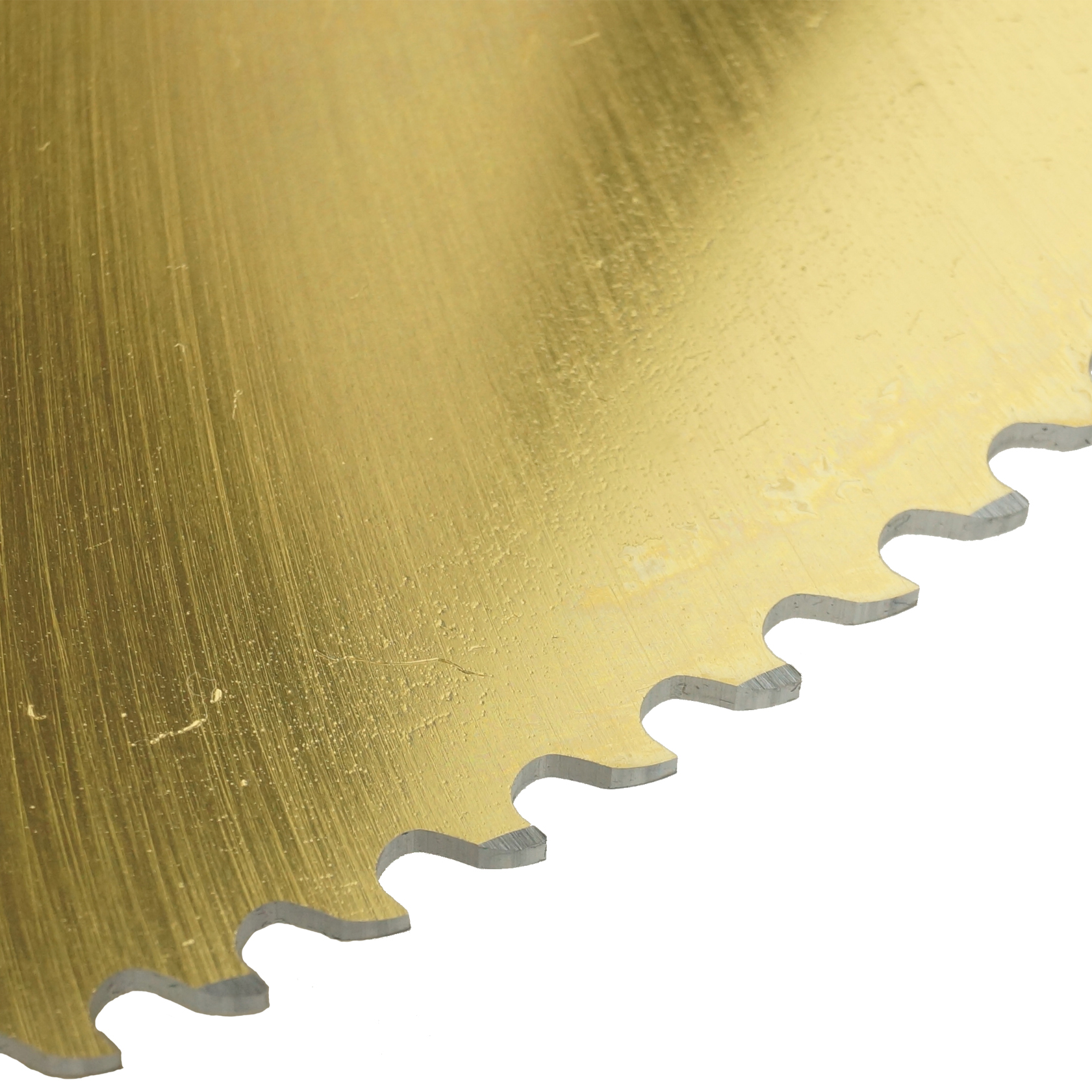

HSS Circular Saw Blades for Off-Line Cutting | Cost-Effective & Highly Resharpenable

Overview

The GOBEACTOOL HSS Circular Saw Blade (Off-Line Series) is the reliable, cost-effective workhorse for standard metal cutting operations. HSS (High-Speed Steel) remains the industry standard for general-purpose applications where high initial investment is restricted and maximum speed is not the primary concern. “Off-line cutting” typically refers to using dedicated, slower-speed cutting machines for processing standard materials like carbon steel, mild steel, and general profiles.

Key Technical Features

| Feature Category | GOBEACTOOL Advantage | Performance Benefit |

| 1. HSS Material Grade | Premium M2/M35 Steel: Utilizing high-quality HSS grades known for their excellent balance of hardness and toughness. | Proven Durability: Offers dependable wear resistance and mechanical strength under standard cutting parameters (lower heat environments). |

| 2. High Resharpenability | Generous Tooth Profile: Designed to accommodate multiple regrinds over its lifespan. | Maximum Service Life: Provides the lowest overall tool life cost (Cost Per Cut) in its category through extensive re-sharpening cycles. |

| 3. Tooth Geometry | Optimized Tooth Forms (BW/HZ): Available in forms specifically suited for cutting tubes, solid bars, and profiles. | Versatile Application: Ensures a clean cut and efficient chip removal across a wide range of standard structural materials. |

| 4. Surface Treatment | Steam-Oxidized or TiN Coated Options: Standard steam oxidation reduces friction and prevents chips from sticking (standard finish). TiN coating is optional for improved performance. | Enhanced Friction Reduction: The dark oxide layer holds lubricant effectively and slightly increases resistance to pick-up. |

Ideal Application Suitability (Off-Line Processes)

The HSS blade is optimized for lower-RPM, heavy-duty machines where the cutting process is not integrated into a high-speed production line:

-

General Fabrication & Workshops: Cutting standard pipes, tubes, and bars.

-

Maintenance & Repair: Used for versatile, medium-volume cutting tasks.

-

Low-to-Medium Speed Machines: Excellent for traditional cold sawing machines without extreme feed rates.

HSS circular saw blade off-line cut

Features:

1. Superhard PVD Composite Coating

2. High temperature resistance, low coefficient of friction

3. Ultra-precision machining process

Application parameters

V=120-180m/min

Sz=0.02-0.05mm

Dimensions

| 250 | 1.2 | 32/40 | 64/80/100/110/128/160/200/240 |

| 250 | 1.6 | 32/40 | 64/80/100/110/128/160/200/240 |

| 250 | 2.0 | 32/40 | 64/80/100/110/128/160/200/240 |

| 275 | 1.2 | 32/40 | 72/78/84/96/110/120/144/180/220/280 |

| 275 | 1.6 | 32/40 | 72/78/84/96/110/120/144/180/220/280 |

| 275 | 2.0 | 32/40 | 72/78/84/96/110/120/144/180/220/280 |

| 275 | 2.5 | 32/40 | 72/78/84/96/110/120/144/180/220/280 |

| 300 | 1.2 | 32/38/40 | 80/90/100/110/120/140/160/200/240/320 |

| 300 | 1.6 | 32/38/40 | 80/90/100/110/120/140/160/200/240/320 |

| 300 | 2.0 | 32/38/40 | 80/90/100/110/120/140/160/200/240/320 |

| 300 | 2.5 | 32/38/40 | 80/90/100/110/120/140/160/200/240/320 |

| 315 | 1.6 | 32/40 | 72/80/90/100/110/1207140/160/200/250/320 |

| 315 | 2.0 | 32/40 | 72/80/90/100/110/1207140/160/200/250/320 |

| 315 | 2.5 | 32/40 | 72/80/90/100/110/1207140/160/200/250/320 |

| 325 | 1.6 | 32/40 | 90/100/110/130/150/170/200/250/320 |

| 325 | 2.0 | 32/40 | 90/100/110/130/150/170/200/250/320 |

| 325 | 2.5 | 32/40 | 90/100/110/130/150/170/200/250/320 |

| 350 | 1.6 | 32/40/50 | 80/90/110/120/140/160/180/220/280/350 |

| 350 | 2.0 | 32/40/50 | 80/90/110/120/140/160/180/220/280/350 |

| 350 | 2.5 | 32/40/50 | 80/90/110/120/140/160/180/220/280/350 |