描述

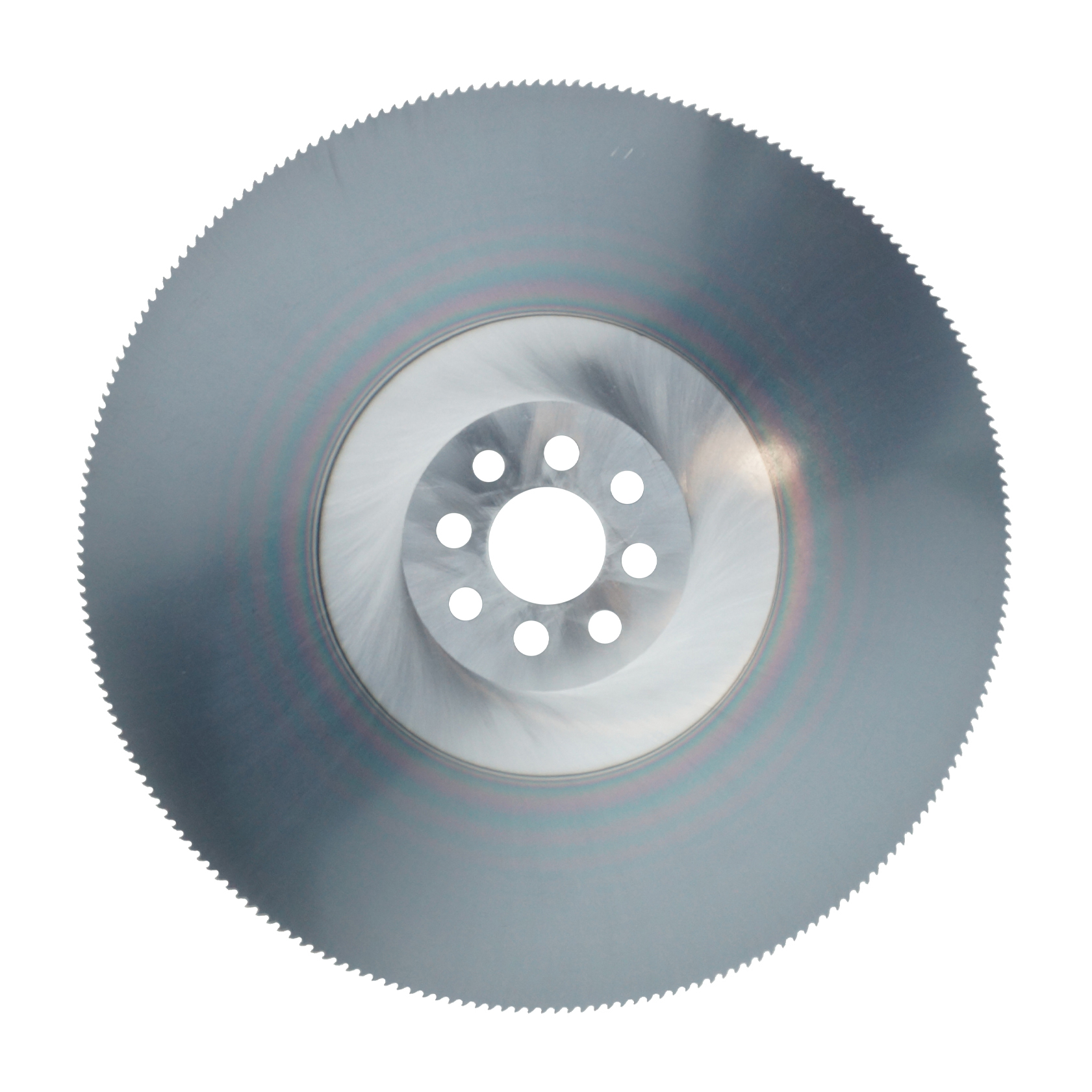

HSS Circular Saw Blades for On-line Cutting | Cost-Effective, High-Volume Reliability

Overview

The GOBEACTOOL HSS Circular Saw Blade (On-line Series) is specifically engineered for continuous, high-volume production lines, primarily in flying saw or high-speed cut-off applications where cost-efficiency and high resharpenability are the key priorities. Utilizing premium M2 or M35 High-Speed Steel, these blades offer a robust and dependable solution for cutting common materials like carbon steel, mild steel tubes, and small profiles at production line speeds. While slower than Cermet, the HSS blade provides superior cost per cut through its long service life and high number of regrind cycles.

Key Technical Features

| Feature Category | GOBEACTOOL Advantage | Performance Benefit |

| 1. HSS Material Grade | Premium M2/M35 Steel: Selected for exceptional balance between hardness and toughness, optimized for medium-speed continuous operation. | Proven Reliability: Provides consistent performance and predictable wear behavior necessary for minimizing unexpected downtime on production lines. |

| 2. High Resharpenability | Generous Tooth Stock: Designed with sufficient material to withstand repeated grinding cycles. | Lowest TCO: Maximizes the blade’s lifetime value, allowing for numerous resharpenings to ensure the lowest operational cost per cut. |

| 3. Geometry for Continuous Feed | Optimized Tooth Forms (BW/HZ): Geometry is engineered to manage the continuous chip load and constant engagement required by on-line flying saw mechanisms. | Efficient Chip Evacuation: Reduces friction and heat build-up, promoting a cleaner cut and extending time between resharpenings. |

| 4. Surface Treatment | Advanced Surface Finish: Steam-oxidized (Black Oxide) is standard, providing a micro-porous surface that holds lubricant effectively. | Friction Reduction: Minimizes material pick-up and reduces frictional heat, crucial for maintaining edge integrity in continuous cutting. |

Ideal Application Suitability

This blade is the go-to solution for cost-sensitive, high-volume continuous metal processing:

-

High-Speed Flying Saws: Cutting tubes and profiles directly on the production line (e.g., ERW or HF welded tube mills).

-

Mass Production Lines: Applications where the material is moving continuously and the cut must be instantaneous.

-

Materials: Thin-to-medium wall thickness steel tubes, light profiles, and general carbon steel.

-

Equipment: Dedicated on-line tube cutting machines and continuous cut-off systems.

HSS circular saw blade off-line cut

Features:

1. Superhard PVD Composite Coating

2. High temperature resistance, low coefficient of friction

3. Ultra-precision machining process

Application parameters

V=120-180m/min

Sz=0.02-0.05mm

Dimensions

| 250 | 1.2 | 32/40 | 64/80/100/110/128/160/200/240 |

| 250 | 1.6 | 32/40 | 64/80/100/110/128/160/200/240 |

| 250 | 2.0 | 32/40 | 64/80/100/110/128/160/200/240 |

| 275 | 1.2 | 32/40 | 72/78/84/96/110/120/144/180/220/280 |

| 275 | 1.6 | 32/40 | 72/78/84/96/110/120/144/180/220/280 |

| 275 | 2.0 | 32/40 | 72/78/84/96/110/120/144/180/220/280 |

| 275 | 2.5 | 32/40 | 72/78/84/96/110/120/144/180/220/280 |

| 300 | 1.2 | 32/38/40 | 80/90/100/110/120/140/160/200/240/320 |

| 300 | 1.6 | 32/38/40 | 80/90/100/110/120/140/160/200/240/320 |

| 300 | 2.0 | 32/38/40 | 80/90/100/110/120/140/160/200/240/320 |

| 300 | 2.5 | 32/38/40 | 80/90/100/110/120/140/160/200/240/320 |

| 315 | 1.6 | 32/40 | 72/80/90/100/110/1207140/160/200/250/320 |

| 315 | 2.0 | 32/40 | 72/80/90/100/110/1207140/160/200/250/320 |

| 315 | 2.5 | 32/40 | 72/80/90/100/110/1207140/160/200/250/320 |

| 325 | 1.6 | 32/40 | 90/100/110/130/150/170/200/250/320 |

| 325 | 2.0 | 32/40 | 90/100/110/130/150/170/200/250/320 |

| 325 | 2.5 | 32/40 | 90/100/110/130/150/170/200/250/320 |

| 350 | 1.6 | 32/40/50 | 80/90/110/120/140/160/180/220/280/350 |

| 350 | 2.0 | 32/40/50 | 80/90/110/120/140/160/180/220/280/350 |

| 350 | 2.5 | 32/40/50 | 80/90/110/120/140/160/180/220/280/350 |