描述

Off-Line Tube and Profile Cutting Saw Blade | Versatile, High-Efficiency Metal Shop Solution

Overview

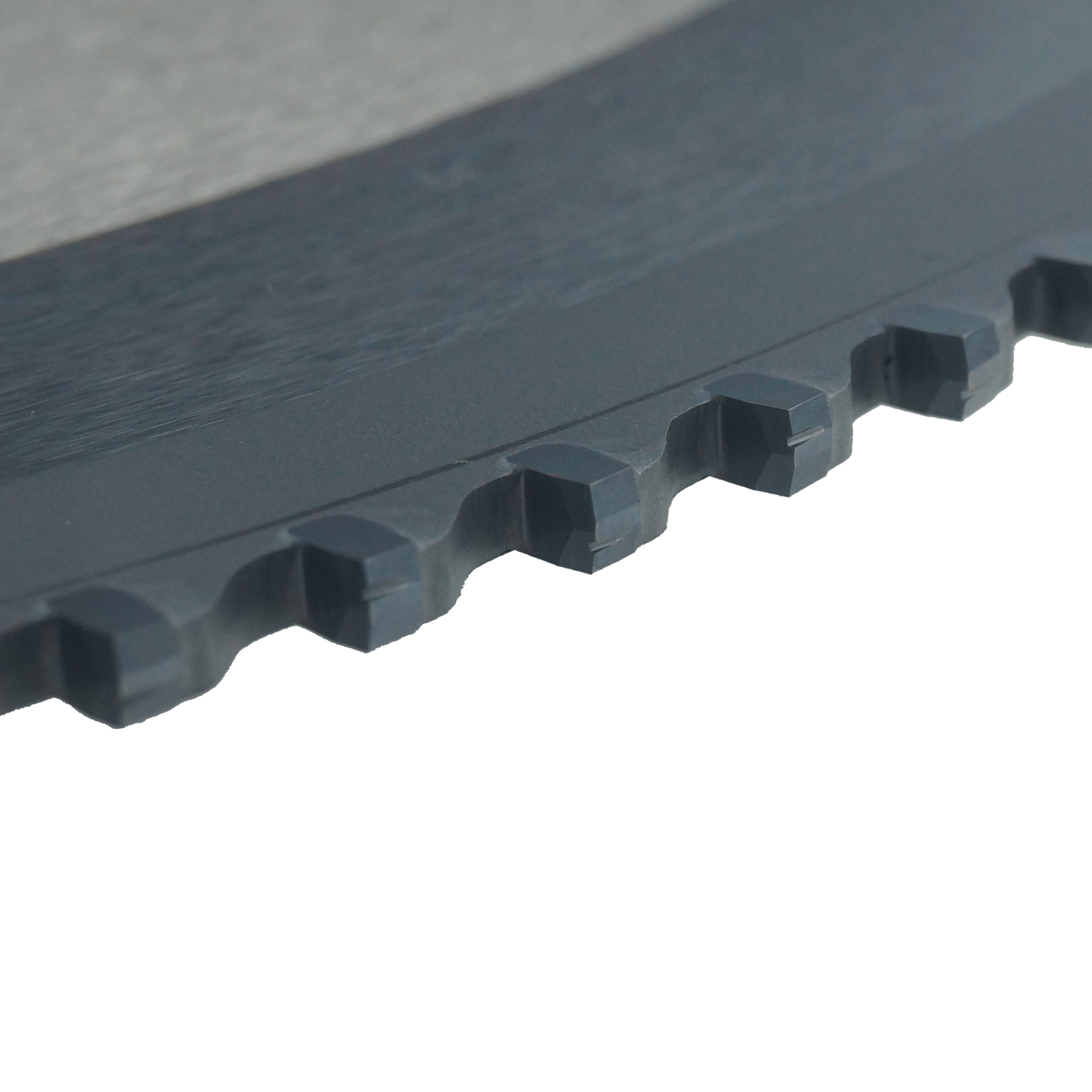

The GOBEACTOOL Off-Line Tube Cutting Saw Blade is the ideal solution for workshops, service centers, and manufacturers requiring a versatile, reliable tool for cutting a variety of pre-finished or structural tubes and profiles. Unlike continuous mill blades, this saw is optimized for intermittent, high-precision cutting on dedicated sawing machines (e.g., manual, semi-automatic, or automatic circular saws). It offers an excellent balance of speed, longevity, and affordability for processing common materials like carbon steel, mild steel, and aluminum profiles.

Key Technical Features

| Feature Category | GOBEACTOOL Advantage | Performance Benefit |

| 1. Universal Geometry | Adjusted Tooth Profile: Features a general-purpose tooth geometry (often TCG or modified BW) optimized for efficient chip management in both thick-walled tubing and solid profiles. | Versatility: Excellent performance across a broad spectrum of material shapes and wall thicknesses in a single workshop environment. |

| 2. Material Core | High-Grade TCT or Cermet Option: Available in durable TCT for cost-effective cutting or Cermet for enhanced wear life on harder materials. | Optimized Lifespan: Offers superior durability and reduced changeover frequency compared to standard HSS blades in general cutting. |

| 3. Precision & Squareness | Strict Runout Tolerances: Manufactured to tight tolerances to ensure maximum flatness and stability on off-line cutting equipment. | High Accuracy: Guarantees straight, perpendicular cuts (squareness) essential for clean joints and welding preparation. |

| 4. Noise and Vibration | Dampening Features: Incorporates tensioning and expansion slots designed to minimize noise and vibration commonly experienced in rigid, stand-alone sawing machines. | Improved Operator Experience: Enhances safety and tool stability during manual or semi-automatic operation. |

Ideal Application Suitability

This blade is the workhorse for flexible, general-purpose metal cutting tasks:

-

Metal Fabrication Shops: Cutting beams, angles, square, and round tubing for structural projects.

-

Steel Service Centers: Processing customer-specific cut lengths and preparing materials for delivery.

-

Maintenance & Repair Workshops: Versatile cutting of various materials and sizes.

-

Equipment: Manual, semi-automatic, and automatic cold saw machines.

Thick wall & square pipe cut

Features:Steel tube orbital cut-off on line

Application parameters

V=300-380m/min

Sz=0.08-0.15mm

Service life: 5-8m2

| Outside diameter(mm) | Kerf(mm) | Saw body thickness(mm) | Borehole(mm) | Sawtooth count |

| 250 | 3.2 | 2.5 | 45/50 | 64/72/80 |

| 300 | 3.2 | 2.5 | 80 | 52/64/72 |

| 355 | 4.0 | 3.2 | 45/80 | 64/72/84 |

| 380/400 | 4.0 | 3.2 | 115 | 52/64/72 |