描述

Zero-Scarf Cermet Flying Saw Blade | Eliminate Secondary Finishing in Welded Tube Mills

Overview

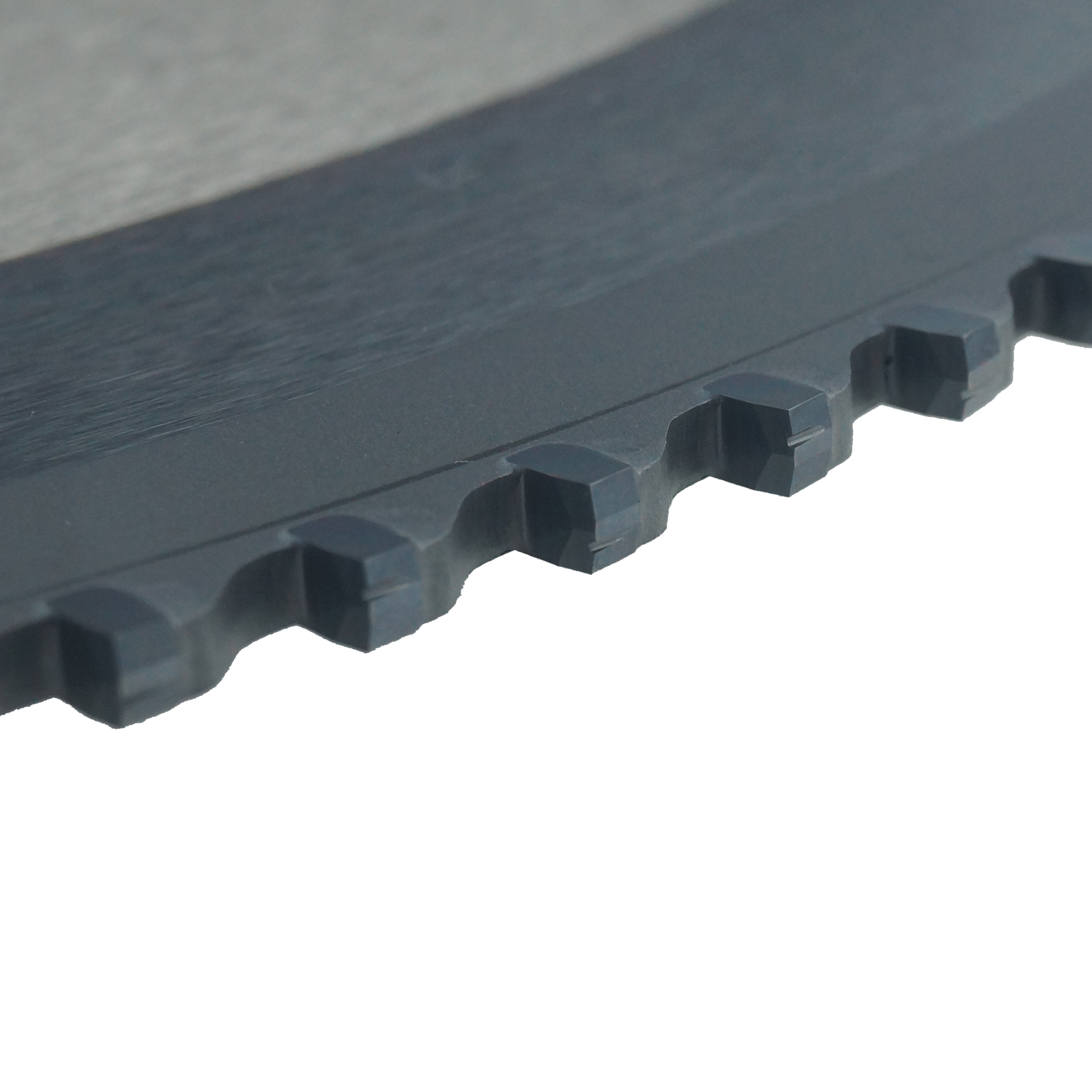

The GOBEACTOOL Orbital/Planetary Saw Blade is a highly specialized tool designed for precision cutting of steel tubes and pipes, often used in off-line or secondary processing applications where maximum cut quality is paramount. Unlike conventional circular saws, orbital cutting involves the saw blade rotating around the stationary pipe (or vice-versa), enabling a cleaner, virtually burr-free finish and superior dimensional accuracy on thick-walled or high-strength materials. This blade is engineered for stability and minimal vibration within orbital saw systems.

Key Technical Features

| Feature Category | GOBEACTOOL Advantage | Performance Benefit |

| 1. Specialized Geometry | Optimized Tooth Profile for Orbital Motion: Features a robust tooth pitch and geometry designed to manage continuous, radial engagement with the pipe wall. | Superior Finish: Achieves smooth, square cuts with minimal to zero internal/external burr, often eliminating the need for post-cut processing. |

| 2. Material Core | High-Impact Cermet or TCT: Utilizes a custom grade of Cermet or High-Impact Tungsten Carbide, depending on the material’s hardness and wall thickness. | Extended Lifespan: Maintains cutting edge integrity through the full 360-degree cycle of the cut, maximizing durability. |

| 3. Dimensional Accuracy | Strict Runout Tolerances: The blade is manufactured and balanced to extremely tight tolerances crucial for orbital systems. | High Precision: Guarantees precise cut length and high perpendicularity (squareness) to the tube axis. |

| 4. Stability & Heat Management | Advanced Tensioning: The blade body is precisely tensioned to resist thermal expansion and stress during the full rotation. | Reliable Performance: Ensures the blade remains stable and flat throughout the entire orbital process, minimizing vibration and noise. |

Ideal Application Suitability

This blade is the precision solution for demanding tube and pipe cutting requirements:

-

Hydraulic and Pneumatic Systems: Cutting tubes that require extremely clean internal surfaces (contamination prevention).

-

High-Strength Tubing: Processing thick-walled stainless steel or alloy steel pipes where integrity is critical.

-

Secondary Manufacturing: Used in dedicated orbital cutting machines for finished part preparation.

Thin wall & roud pipe cut

Features:Steel tube orbital cut-off on line

Application parameters

V=300-380m/min

Sz=0.08-0.15mm

Service life: 5-8m2

| Diameter | Kerf | B | Bore | Teeth |

| 250 | 3.2 | 2.5 | 45/50 | 64/72/80 |

| 300 | 3.2 | 2.5 | 80 | 52/64/72 |

| 355 | 4.0 | 3.2 | 45/80 | 64/72/84 |

| 380/400 | 4.0 | 3.2 | 115 | 52/64/72 |