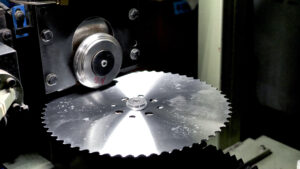

Purchasing a high-performance GOBEACTOOL saw blade is only the first step toward achieving superior cutting efficiency. The true cost-effectiveness and longevity stem from precise tool management and professional maintenance. Many factories waste millions annually simply by neglecting critical details in their regrinding and management practices.

This article reveals how a data-driven approach can ensure your Cermet cold saw blades consistently achieve, or even exceed, 2.5 times the industry average lifespan.

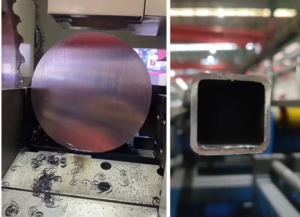

I. Precision Regrinding: The 80% That Determines Lifespan

Regrinding is the single most critical factor in extending tool life. Incorrect regrinding can not only shorten the blade’s life but may lead to premature scrap.

1. Strictly Control Grinding Stock ()

- Data Principle: The material removal amount (△T) on the tip during each regrind must be strictly controlled, typically between 0.2mm and 0.3mm.

- Benefit: Excessive grinding consumes valuable tip material, reducing the total available Re-Grind Cycles. Precise, minimal removal ensures the blade maintains maximum tip thickness until the cycle limit.

2. Ensure Correct Geometry Angles ()

- Data Principle: CNC grinders must be used to restore the original rake angle (γ) and clearance angle (α) of the blade, especially for complex profiles (like those on flying saws).

- Benefit: Deviations in geometry directly alter the single tooth load and chip flow, leading to issues ranging from rough surface finish to catastrophic chipping. Restoring original angles is vital for maintaining performance and tip integrity.

3. Prevent Thermal Damage and Micro-Cracks

- Data Principle: High-quality coolant must be used during the regrinding process, and feed rates must be stabilized to control the temperature in the grinding zone below the material’s permissible threshold.

- Benefit: Overheating can cause micro-cracks in the Cermet tip. These cracks rapidly propagate when the blade is subsequently put under cutting load, leading to premature failure.

II. Tool Management: Daily Habits That Extend Lifespan

The longevity of a high-performance saw blade is dictated by your daily operational habits and record-keeping.

1. Set Precise Change-Out Criteria (Vb)

- Data-Driven: Do not wait until the blade shows obvious chipping or severe cut deterioration. A scientific change-out point should be based on the flank wear (Vb). For high-performance Cermet blades, replacement should occur when Vb reaches between 0.15mmand 0.2 mm.

- Benefit: Changing out early minimizes the required grinding stock, maximizing the number of regrinds. Changing out after excessive wear results in significant tip damage, drastically reducing the usable life.

2. Establish Detailed Tool History (Tool History)

- Data Recording: Record for every blade: Total cuts made, number of regrinds, performance after each regrind, last regrind date, and the final reason for scrapping.

- Benefit: Analyzing the history helps you identify the optimal lifespan range for your specific material and machine, and pinpoints the root cause of premature failures (operator error or incorrect parameter settings?).

3. Strict Storage and Transport Protocols

- Standardization: Even tough Cermet tips can be damaged by rough handling. Operators must use dedicated packaging or protective sleeves when transporting or storing reground blades.

- Benefit: Prevents micro-chipping caused by mechanical impact during non-operational time, ensuring the blade is in perfect condition every time it goes back into the machine.

III. Conclusion: Data Achieves High Efficiency

The GOBEACTOOL Cermet blade provides the foundation for long life, but your factory’s data-driven management and precision regrinding process determine the final benefit. By scientifically managing grinding stock, change-out points, and tool history, achieving 2.5x the industry average lifespan is entirely achievable, making this the most direct path to lowering your TCO and boosting your competitive edge.

📞 If your current maintenance provider struggles to meet these standards, contact a GOBEACTOOL-certified service partner to ensure your blades receive OEM-level maintenance.